Sectors

Tailored Industrial Solutions for Enhanced Efficiency and Competitiveness

We deliver customized solutions designed to boost operational efficiency and competitiveness across all industrial sectors. Our technical expertise and ability to integrate advanced technologies enable us to support clients in optimizing production and logistics processes, ensuring measurable and sustainable results.

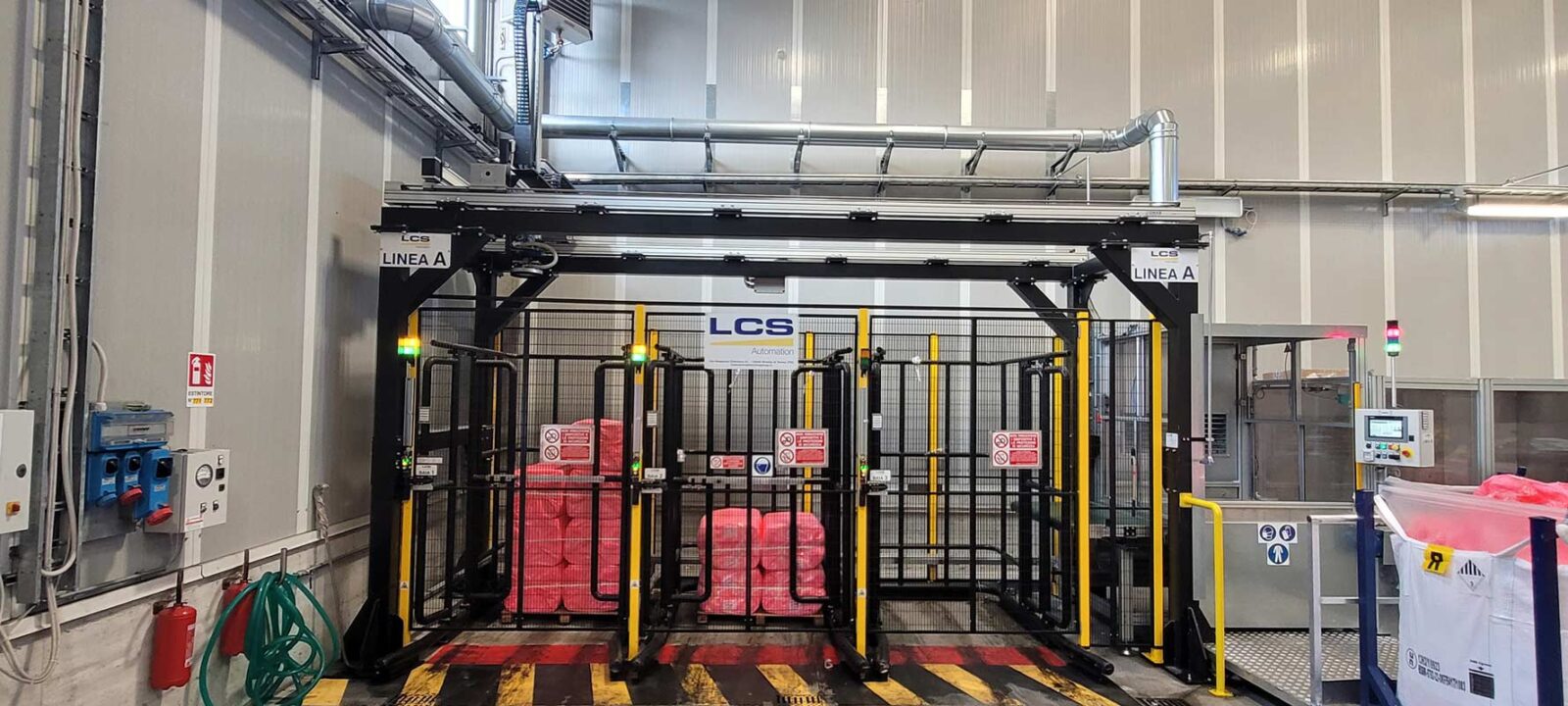

Over the decades, LCS Group has successfully implemented projects in various industries for leading companies such as Barilla, Kuehne + Nagel, Pirelli, Istituto De Angeli, Ambrovit, and many others.

3PL

- Key Challenges in the 3PL Sector Addressed by Automation:

Management of Diverse SKUs

Automated storage, picking, and material handling processes reduce cycle times and increase productivity.

Speed and Accuracy in Deliveries

Automation minimizes manual errors, enhances order fulfillment accuracy, and lowers costs related to returns and mistakes.

Space Optimization

Automated systems maximize storage density and efficiency, reducing waste and operational costs.

Improved Working Conditions

Automation reduces physically demanding tasks, enhancing workplace safety and operator well-being.

- What We Offer

Multi-client Warehouse Management Systems (WMS)

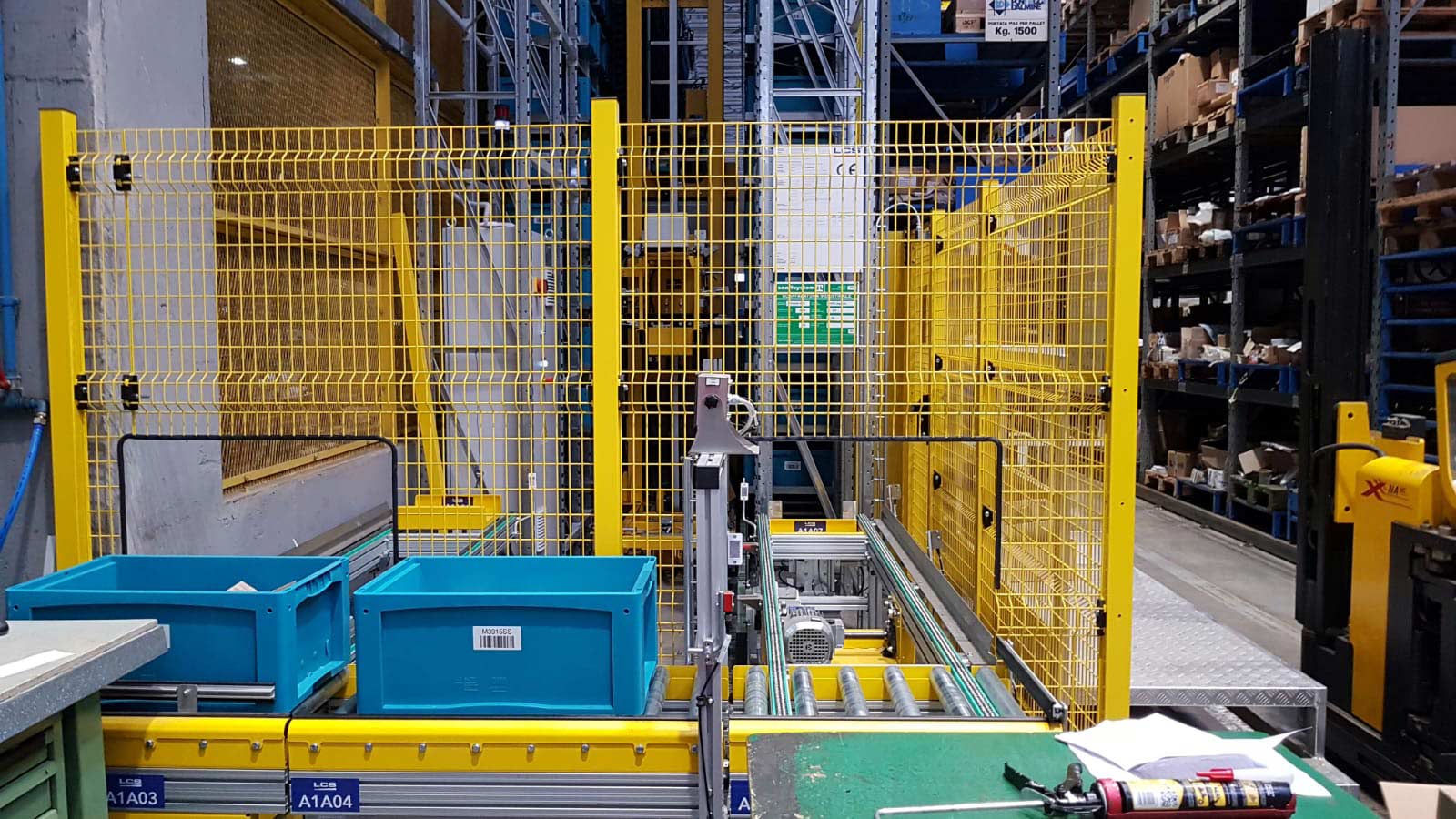

Automated storage and handling systems

Parcel sorters for efficient item distribution

Cross-client standard plant solutions for integrated and streamlined operations

Airports

- Key Challenges in the Airport Sector Solved by Automation

High Traffic Volume Management

Automation handles large volumes of baggage, passengers, and cargo efficiently, reducing bottlenecks and lost items.

Speed and Timeliness

Automated systems accelerate loading and unloading operations, ensuring flight schedule adherence.

Passenger and Staff Safety

Reduced manual handling lowers accident risks and enhances overall safety.

Security and Regulatory Compliance

Advanced technologies automate baggage and cargo checks, ensuring compliance with international safety standards.

- What We Offer

Baggage reconciliation systems (passenger-baggage matching)

Baggage Handling Systems (BHS) & cargo sorting solutions

Integrated hardware and software platforms for optimized airport logistics

Automotive

- Key Challenges in the Automotive Sector Solved by Automation:

Just-in-Time & Just-in-Sequence Logistics

Le case automobilistiche e i loro fornitori operano secondo logiche produttive in cui ogni componente deve arrivare nel momento e nella sequenza esatta richiesta dalla linea di assemblaggio. L’integrazione di sistemi automatici per lo stoccaggio, il prelievo e la movimentazione consente di soddisfare questi requisiti con precisione millimetrica.

Performance Monitoring

L’automazione facilita il monitoraggio di KPI essenziali per valutare l’efficienza delle operazioni, identificando punti di forza e aree di miglioramento nella gestione dello stock, delle attività di picking, spedizioni e trasporti.

Safety and Cost Reduction

L’impiego di robot collaborativi, sistemi AMR e soluzioni di movimentazione automatizzata riduce l’intervento umano in operazioni ripetitive e potenzialmente rischiose, migliorando la sicurezza sul lavoro e abbattendo i costi operativi.

- What We Offer

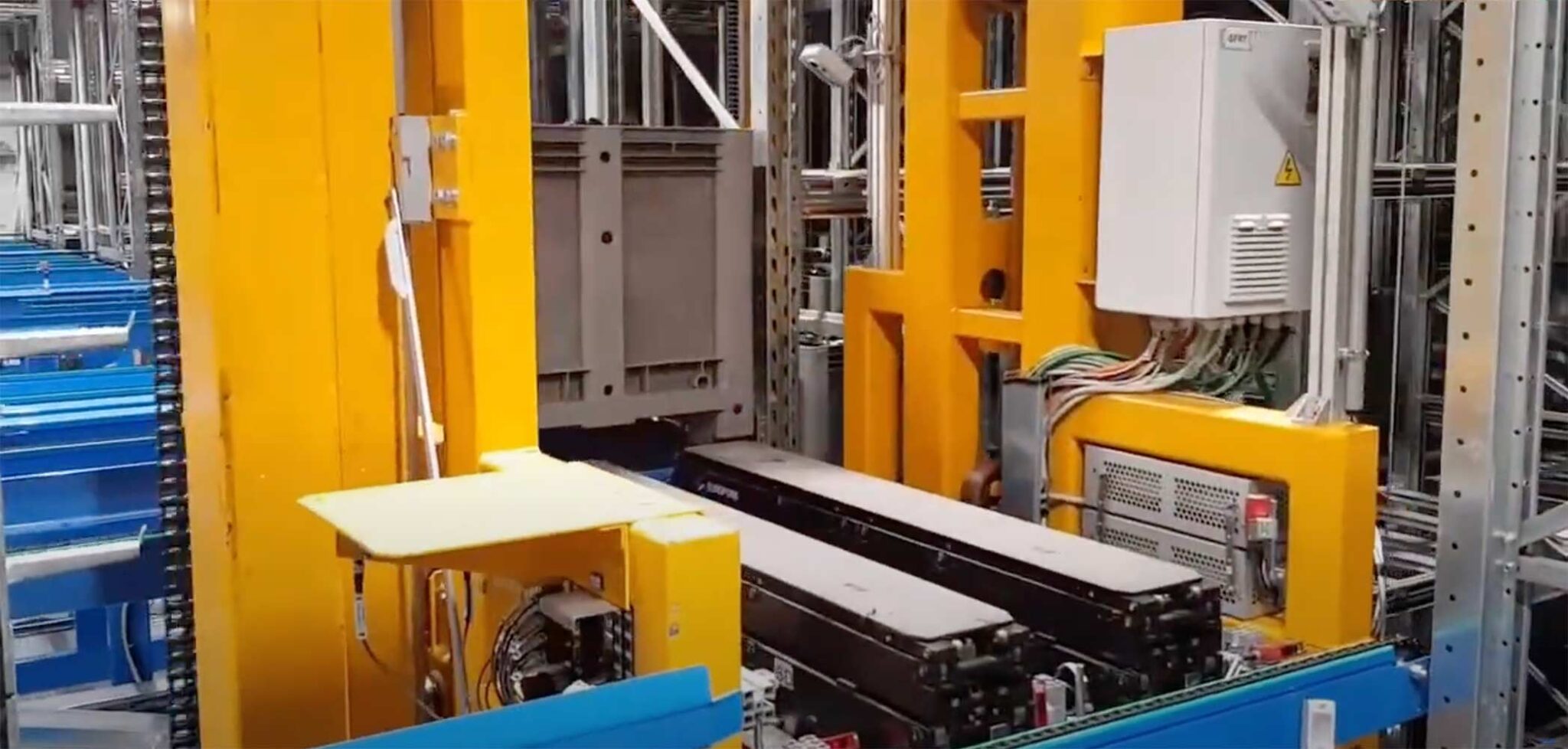

Material handling systems for production lines and internal logistics

Robotic solutions for assembly and specialized processing

Advanced software for production management and control

Automated storage and intelligent picking systems

Distribution & E-Commerce

- Key E-Commerce Challenges Solved by Automation:

High Order Volume Management

Automation enables fast and accurate processing of large order volumes, reducing errors and improving delivery speed.

Scalability During Peak Demand

During high-sales periods like Black Friday, automated systems handle order surges without compromising service quality.

Fulfillment Accuracy for Enhanced Customer Experience

Fast and precise deliveries increase customer satisfaction, loyalty, and brand reputation.

Efficient Returns Management

Automated systems streamline reverse logistics, enabling faster refunds and efficient handling of returned goods.

- What We Offer

Automated picking and sorting solutions

Management systems for high-density distribution centers

Integration of last-mile delivery technologies

Fashion

- Key Industry Challenges Solved by Automation:

Management of Diverse Product Ranges

Automation supports efficient handling of SKUs with varying sizes, colors, and samples, improving warehouse organization and accessibility.

Fast Time-to-Market

Automated logistics and kitting operations accelerate product launches and market responsiveness.

Traceability and Quality Control

Advanced systems ensure full product traceability and compliance with quality standards.

Efficient Returns Processing

Automation simplifies reverse logistics, enabling quick refunds and streamlined handling of returned items.

- What We Offer

Picking systems for high-variability items

Automated solutions for textile warehouse management

Integration of technologies for omnichannel logistics

Food & Beverage

- Key Challenges in the Food Industry Solved by Automation:

Perishable Goods Management

Automated systems ensure proper food preservation, compliance with hygiene standards, and cold chain continuity.

High Inventory Turnover

Advanced storage and picking solutions support high SKU rotation, optimizing slotting strategies and order fulfillment speed.

Product Traceability

Real-time tracking of expiration dates, batches, and serial numbers ensures compliance with food safety regulations.

Regulatory Compliance & Hygiene Standards

Systems are designed to meet HACCP and IFS standards, ensuring safe storage and handling.

Controlled Temperature Environments (-24°C)

Automation reduces human intervention in cold storage, improving operational efficiency and safety.

- What We Offer

Automated picking and packaging systems

Solutions for temperature-controlled warehouse management

Integration of quality control technologies

High-capacity systems for intensive flow and volume management

General industry

- Key General industry Sector Challenges Solved by Automation:

Accuracy and Traceability

Automation ensures precise material control, enabling batch traceability and efficient inventory management.

Operational Flexibility

Automated warehouses can be configured to handle various sizes and types of materials, adapting to the specific requirements of each industry and client.

Integration with Production Processes

Automation facilitates seamless integration between warehouse operations and production lines, improving material flow and reducing downtime.

Scalability

Automated systems can be expanded or modified based on production needs, allowing dynamic resource management.

- What We Offer

Handling systems for heavy materials

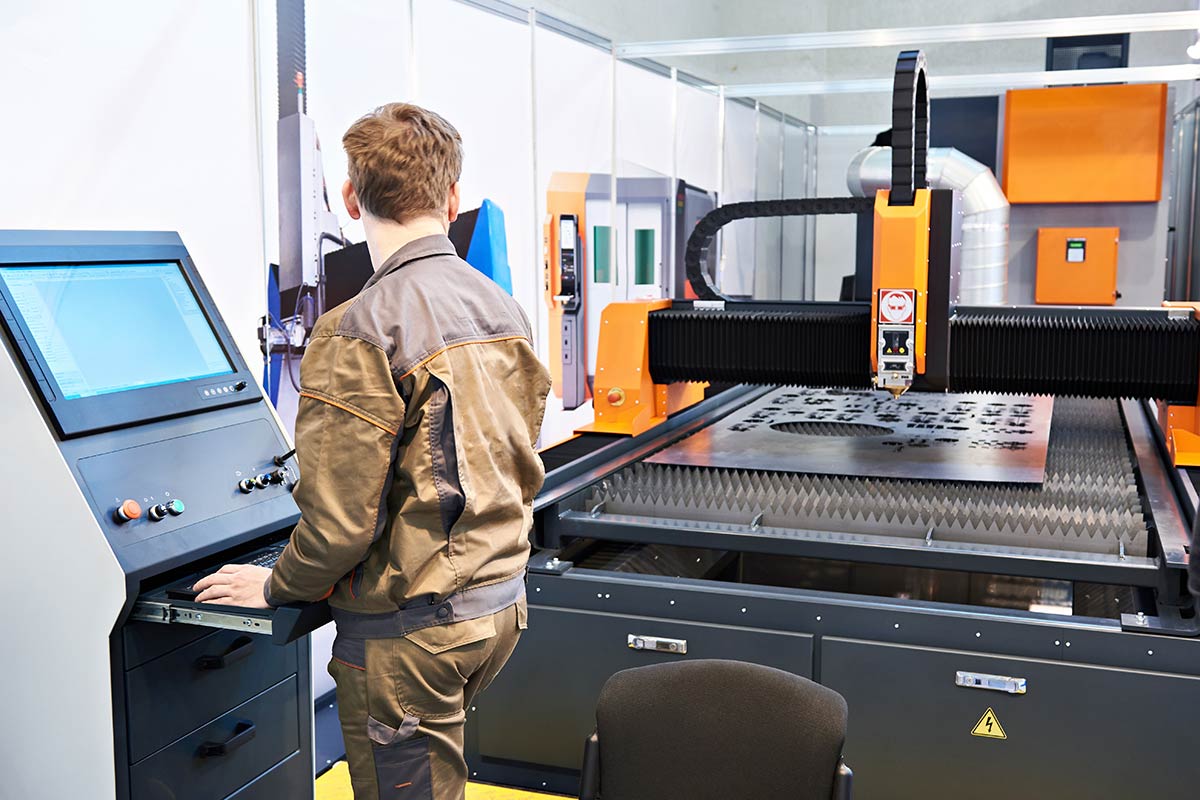

Automation solutions for cutting and machining

Integration of technologies for the management of specialised warehouses

Healthcare

- Key Healthcare Sector Challenges Solved by Automation:

Temperature-Controlled Storage

Automated systems monitor and regulate environmental conditions in real time, ensuring safe storage of temperature-sensitive products like vaccines and medications.

Regulatory Compliance & Qualification Management

Advanced software ensures process validation and compliance with international standards (GMP, GDP, FDA, MDR), minimizing non-compliance risks.

RFID-Based Traceability

Unique identification of pharmaceuticals and medical devices via RFID and serial codes ensures safety and full supply chain visibility.

Zero Downtime & Maximum Reliability

High-reliability automation ensures uninterrupted operations, critical for patient safety and healthcare continuity.

- What We Offer

Temperature-controlled storage systems for thermolabile products

Management and traceability software

Integration of RFID and serial code technologies

Manufacturer

- Key Manufacturing Sector Challenges Solved by Automation:

Handling of Diverse Product Types

Automated storage and handling systems optimize space and streamline access to materials, enhancing production flow.

Fast Time-to-Market

Automation accelerates logistics operations, enabling rapid market response and timely product distribution.

Traceability and Quality Assurance

Automated systems provide full product traceability and support quality control interventions.

Safety and Cost Reduction

Robotic and automated picking systems reduce manual labor, improve operational safety, and enhance efficiency.

- What We Offer

Material handling systems for production lines

Robotic solutions for assembly and processing

Integration of production control software

Metallurgical

- Key Metallurgical Sector Challenges Solved by Automation:

Precision and Traceability

Automation ensures accurate material control, batch traceability, and efficient inventory management.

Operational Flexibility

Automated warehouses adapt to various material sizes and types, meeting the specific needs of the metallurgical industry.

Integration with Production Processes

Automation enhances material flow between storage and production lines, reducing downtime.

Scalability

Systems can be expanded or reconfigured to meet evolving production requirements, enabling dynamic resource management.

- What We Offer