Malpensa cargo

Automation and innovation for air cargo management at Milan Malpensa

Solutions

Automated Warehouse

revamping

Sector

Airports

Challenge

Milan Malpensa Airport, Italy’s leading cargo airport, needed an advanced system for managing cargo flows, improving flexibility, reliability, and data processing capacity. It was also necessary to upgrade existing infrastructure for ULD storage and handling, ensuring more efficient cargo management.

Solution

- Construction of two automatic warehouses for air cargo handling

- LogiCARGO system (WCS + WMS) for optimized storage and handling flow management

- Integration of mechanized systems for truck interfacing and ULD management

- Specialized areas for perishable goods and live animal control

- Technological upgrade of the management and control system

Key technical data

- Total cargo area: 180,000 sqm

- Warehouses for air cargo handling: 2

- Automatic mechanized systems for ULD: 1 main + 2 additional for truck interfacing

- Temperature-controlled areas for perishable goods management

- Zones equipped for live animal control (small and large)

- Management software: LogiCARGO (WCS + WMS) for import/export flow optimization

- User-friendly web interface compatible with PC and PDA

Full description of the project

Milan Malpensa Airport, Italy’s leading cargo hub and one of the top ten freight airports in Europe, entrusted LCS Group with the development of Cargo City, a 180,000 m² area dedicated to air cargo handling, storage, and processing. The facility is designed to manage a wide range of unit load devices (ULDs) and special cargo, including temperature-controlled warehouses, live animal handling zones, and spaces for customs and health authorities.

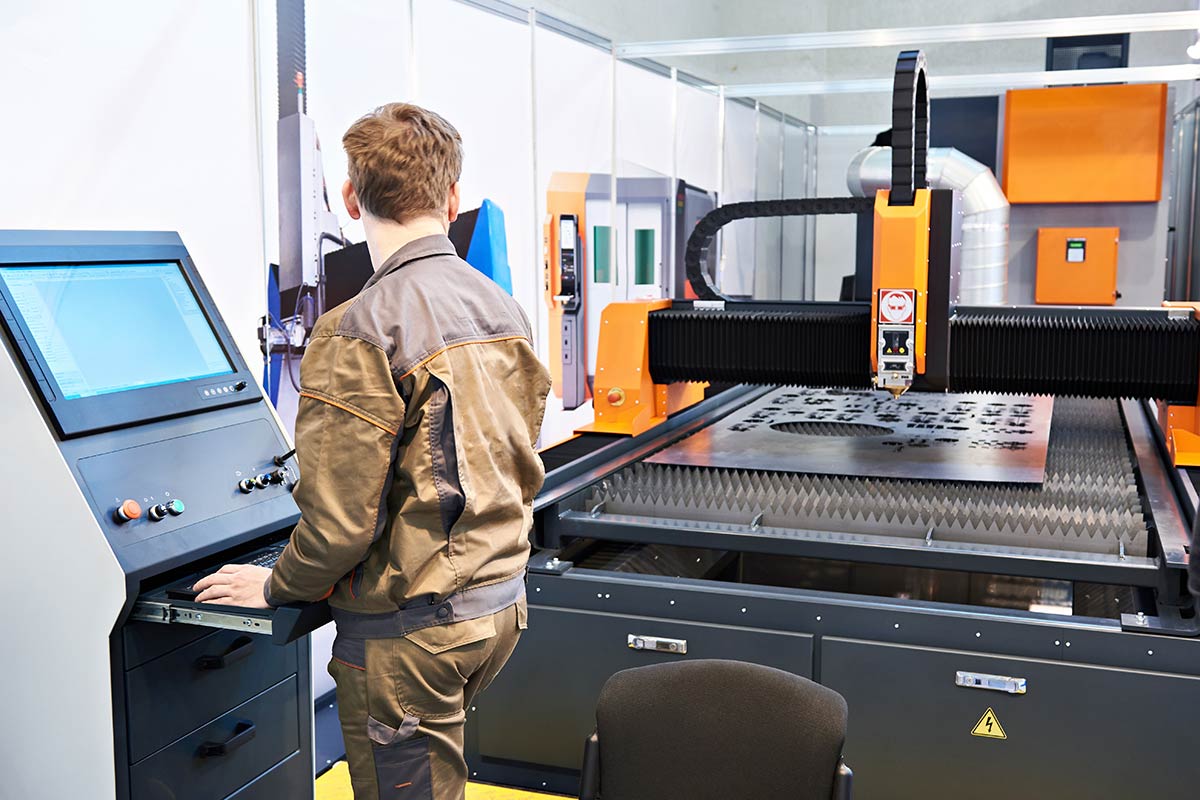

LCS implemented a fully automated and mechanized system for ULD storage and movement, complete with truck interfaces, two automated vertical warehouses for cargo break-down, and four temperature-controlled areas for perishable and sensitive goods.

At the software level, the key enabler is LogiCARGO, an integrated WMS + WCS solution that controls import and export flows with accuracy and flexibility. Its web-based interface allows real-time monitoring, detailed analytics, and process optimization, boosting system reliability and ensuring end-to-end cargo traceability.

The project is part of the Malpensa Smart Cargo City ecosystem, aligned with IATA E-Freight and Cargo 2000 initiatives, providing freight forwarders and logistics operators with digital tools for load booking, customs clearance, shipment monitoring, and weather tracking. Fully compatible with major ERP systems, the platform supports paperless cargo operations, enhancing efficiency, compliance, and sustainability.

LCS also contributed to the ground logistics infrastructure, including the first CEF-certified secure truck parking area with 154 bays, EV charging stations, rest facilities for drivers, and safety services — part of the €27.5 million Pass4Core project co-funded by the European Union.

In July 2024, U-ELCOME, a pioneering drone freight project, was tested inside Cargo City in partnership with Technosky and Telespazio. The trials demonstrated last-mile drone delivery for cargo logistics within airport premises, opening the door to innovative, sustainable, U-Space-enabled operations.

With this project, LCS transformed Malpensa Cargo City into a state-of-the-art logistics hub, combining automation, software integration, and digitalization to deliver unmatched efficiency, reliability, traceability, and sustainability in air cargo handling.