Skip to content

Limonta

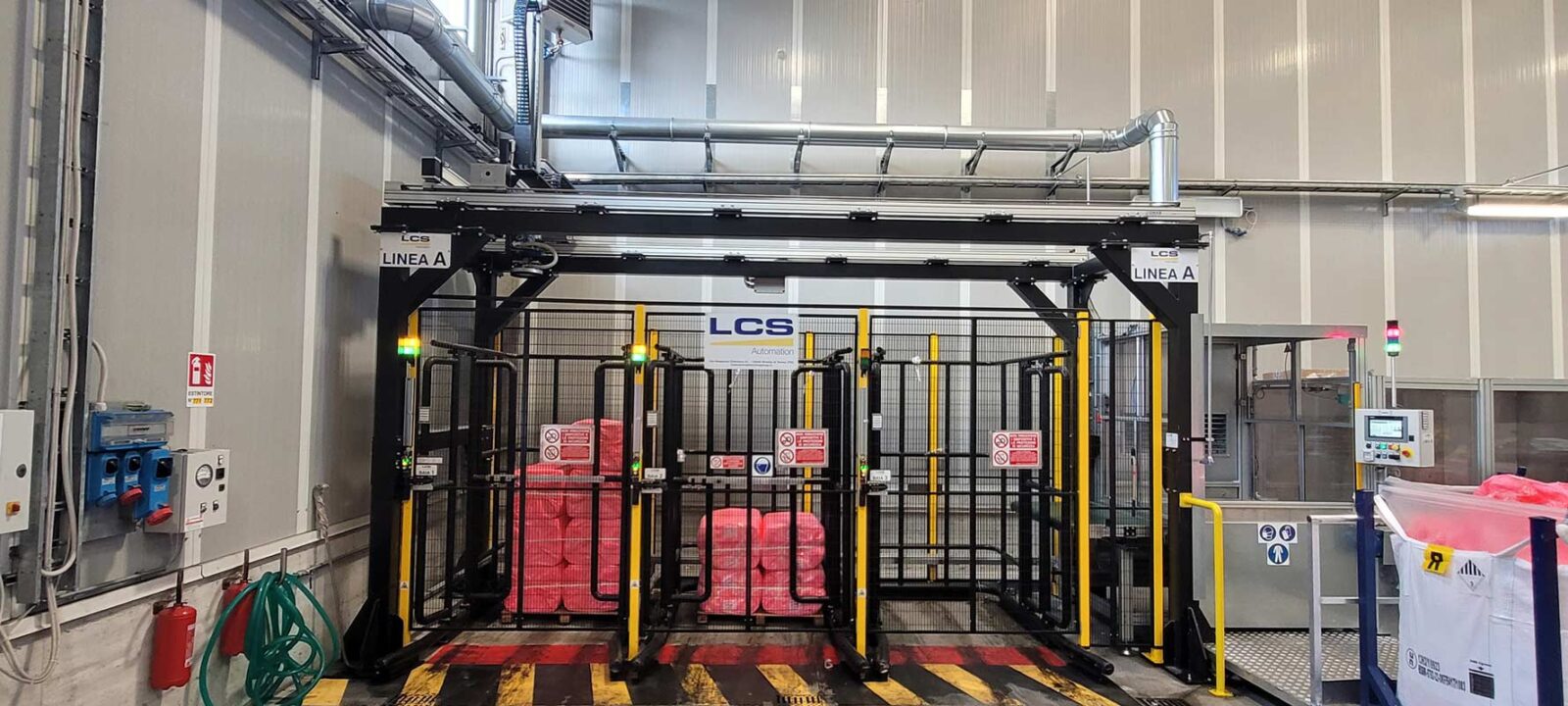

Revamping of the Automatic Warehouse and Automatic Picking Solution

Solutions

Automated Warehouse

software

revamping

Sector

Fashion

Challenge

The Limonta Group, a family-owned company with a long textile tradition, needed to automate and make intralogistics processes more efficient to support business growth. The goal was to improve the picking of fabric rolls and optimize the automatic warehouse, while ensuring high attention to detail and excellent customer service.

Solution

LCS designed and implemented a project divided into two phases:

Revamping the automatic warehouse with software updates (WMS and WCS), stacker cranes, and conveyor PLCs.

Implementing an automatic picking system for fabric rolls, based on a mechanized structure with conveyors, barcode readers, and advanced management software. This brought the following benefits:

- 70% reduction in fabric roll movements with the same shipping volume

- Tripled plant productivity

- Reduction in shipping lead time from 2-3 days to 1 day

- Improved ergonomics for operators, now engaged in supervisory tasks instead of manual handling

- Enhanced customer satisfaction, thanks to greater precision and reliability in deliveries

Key technical data

- Automatic warehouse: revamping with WMS and WCS replacement

- Picking system: 20 bins/hour overturned, 400 fabric rolls/hour managed 24/7 monitoring with cameras and remote assistance

- Maintenance contract for stacker cranes and picking system