Colma

New Automated Warehouse with Put-to-Light System

Solutions

Automated Warehouse

Sector

Manufacturer

Challenge

Colma Srl, a company specializing in aluminum trade and accessories for fixtures, required a system to enhance order fulfillment speed and accuracy while optimizing internal logistics and reducing processing times.

Solution

- Picking and order sorting stations with a put-to-light system

- Implementation of an automated pallet warehouse

- Management of 8 different types of handling units (UdC)

- 3 aisles served by 3 stacker cranes

- Dual straight shuttle for pallet sorting

- Dimension and weight control at entry points

- Empty pallet warehouse with a capacity of 13 pallets

- Put-to-light system for optimized storage operations

- LCS LogiCon software interfaced with WMS LogiWare and company ERP

Key technical data

- Automated pallet warehouse with picking stations

- 8 UdC types (4 with 800×1200 base, 4 with 1120×1200 base)

- Inbound/outbound capacity: 90 UdC per hour in, 90 UdC per hour out (180 UdC/hour total)

- 3 aisles with 3 stacker cranes

- Dual straight shuttle for pallet sorting

- Empty pallet storage for 13 pallets

- Put-to-light system with a maximum capacity of 8 lists per operator

Full description of the project

Colma Srl, a leading company in the aluminum and window accessory trade, has recently invested in a new automated warehouse at its headquarters in Teverola (CE). The project, entrusted to LCS, aimed to deliver a state-of-the-art logistics system tailored to Colma’s operational needs, improving speed, accuracy, and reliability in order fulfillment.

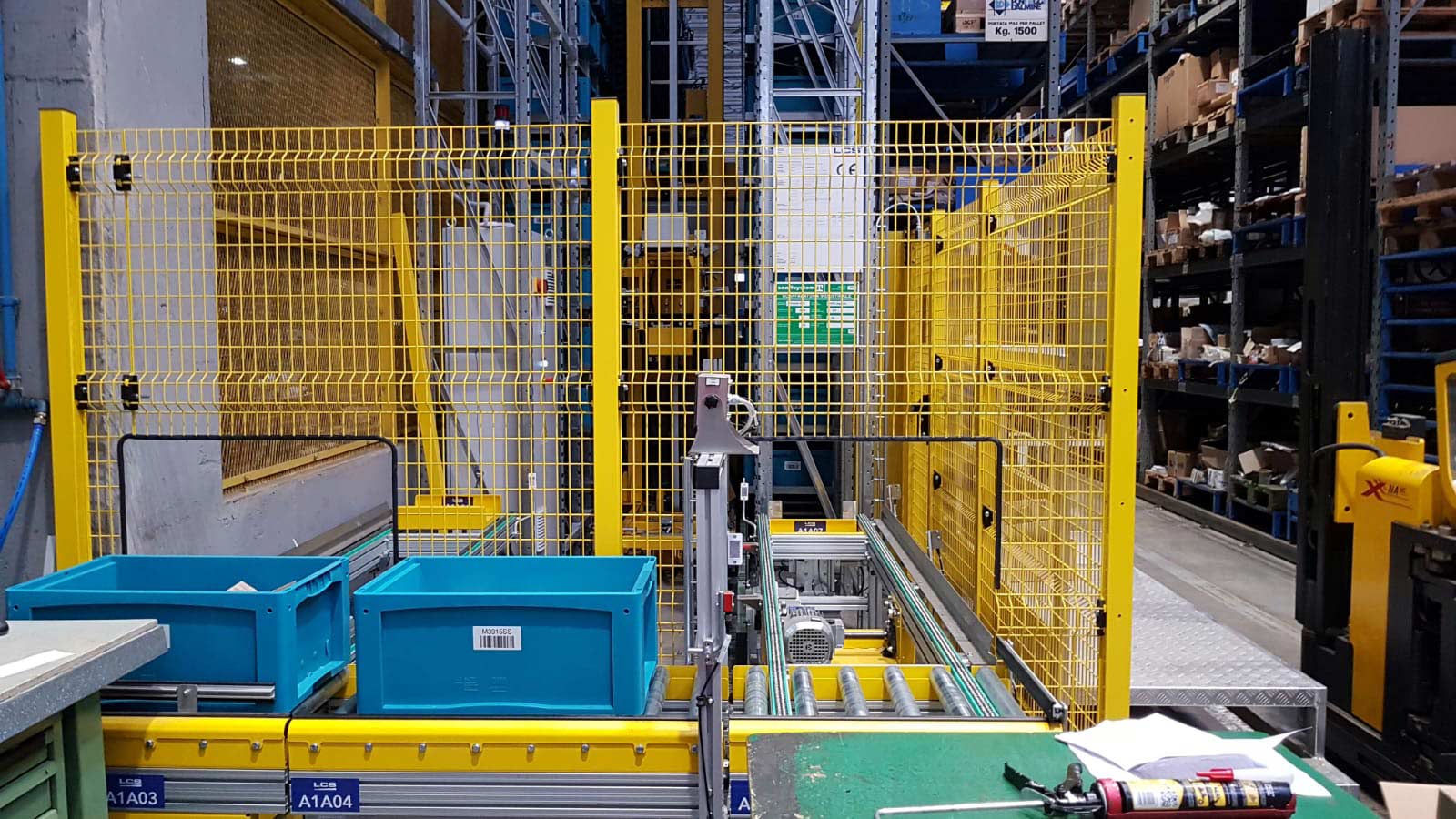

Installed within an existing facility, the system features an advanced picking and order sorting solution based on put-to-light technology, designed to optimize goods handling and streamline logistics flows.

The warehouse manages eight types of load units (LUs) and handles 90 inbound and 90 outbound LUs per hour, totaling 180 LUs/hour. Accessories for window and door systems—such as hinges, handles, gaskets, and locks—are stored across four levels, using single or double-depth storage depending on LU dimensions.

The handling system includes:

- Three aisles served by stacker cranes

- A dual-track linear shuttle connecting to three loading and picking bays

- A dedicated receiving bay equipped with shape and weight control systems; non-compliant pallets are automatically rejected and returned to the operator

- A dedicated empty pallet warehouse with a capacity of 13 pallets, replenished either manually or automatically

At the core of the system is the put-to-light picking solution, which guides operators through the picking process. Each operator works at an ergonomic station equipped with a lifting table and a light display indicating the location and quantity of items to pick. This ensures high precision in order fulfillment and significantly improves picking and sorting efficiency.

Orders are processed for both external customers and the adjacent retail store, with priority given to counter orders, ensuring fast and responsive service.

Thanks to this automated system, Colma has achieved:

- Improved logistics efficiency

- Reduced picking errors through visual guidance

- Optimized warehouse space utilization

- Enhanced workplace ergonomics, lowering the risk of operator injury

- Increased order handling capacity, accelerating logistics flows and improving customer service responsiveness

In conclusion, the new automated warehouse with put-to-light technology marks a major step forward in Colma’s logistics optimization strategy, enhancing not only operational performance and service quality, but also working conditions for staff. This investment has strengthened the company’s market competitiveness, enabling it to respond more agilely and accurately to customer demands.