Skip to content

Ferrarelle

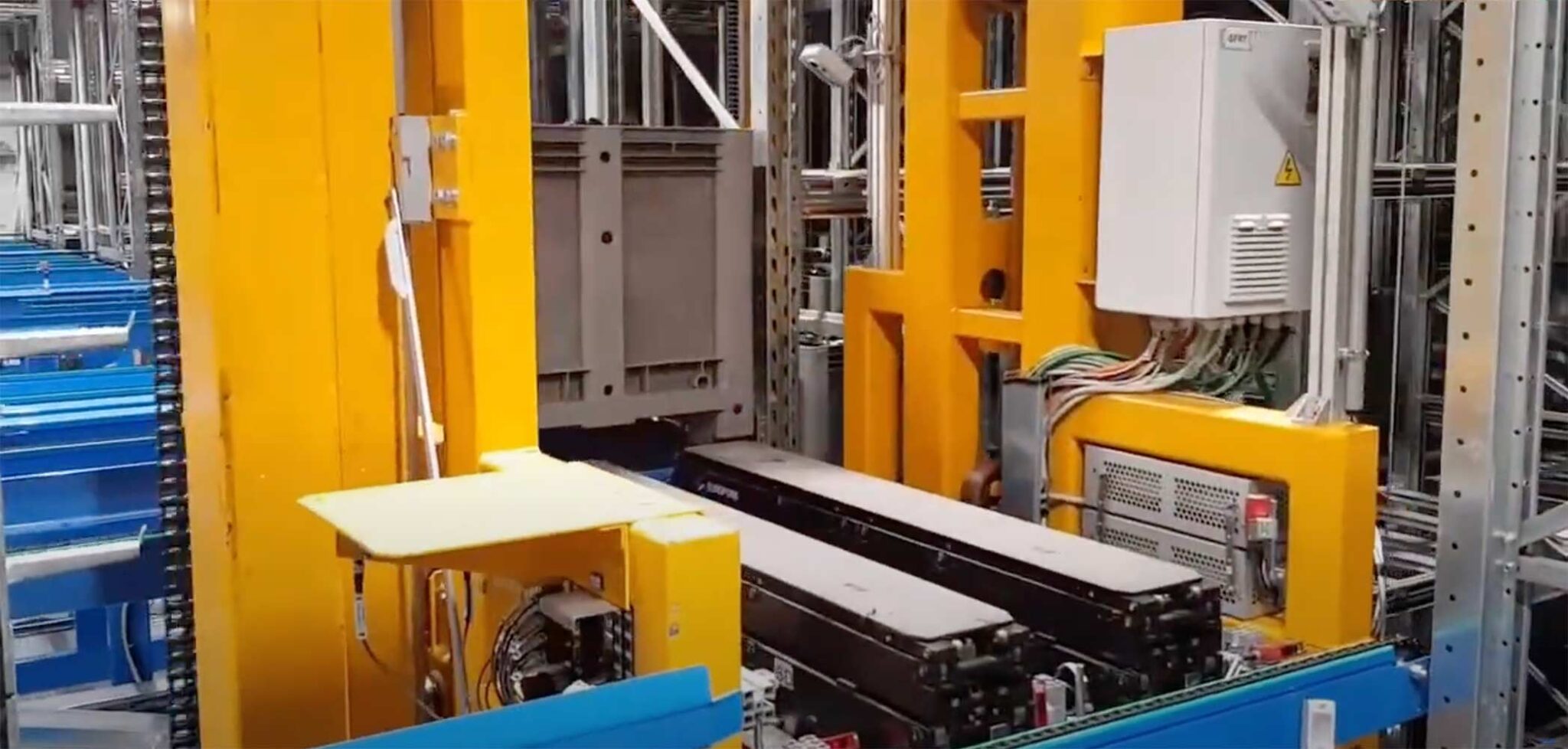

Semi-automated warehouse for production-to-truck loading connection

Solutions

Automated Warehouse

Sector

Food & beverage

Challenge

The goal was to automate the movement of pallets from the production plant to the warehouse facility, ensuring a seamless connection between customer production lines and two semi-automated truck loading points.

Solution

The proposed solution included the design and implementation of an automated warehouse and material handling system, featuring two semi-automated truck unloading lines. The supply included mechanical components, electrical installation for command control, and automation software interfaced with the customer’s WMS.

- Self-supporting mezzanine: 5 meters high.

- Truck loading line: ability to create 3 trains of 32 pallets each.

- Truck unloading line: ability to receive 4 trains of 32 pallets each.

- Material handling system: inbound dimension control, roller/chain conveyors, lifting and rotating tables for pallet deviation, elevators, and sorting shuttles.

- Optimized management: supervision software (LogiCON, LogiTRASP) integrated with the company’s WMS.

Key technical data

- Warehouse height: approx. 11.5 meters

- IN aisles: 3 chain conveyors for profile control

- OUT aisles: Unloading area towards shipments consisting of 4 gravity roller conveyors

- System performance: 200 pallets per hour inbound and 200 pallets per hour outbound

- Managed goods type: Wooden pallets 800 x 1,200 mm.