Automated warehouses

We design and build customized storage solutions

LCS Group develops innovative and scalable storage systems, designed to optimize space and ensure high operational efficiency.

From the handling of pallets, boxes, parcels, and containers to small components, we offer advanced solutions that maximize available space and ensure maximum reliability.

By integrating automated handling systems and WMS (Warehouse Management System) software, we enable real-time inventory tracking and optimal stock management, designing tailor-made projects tailored to specific volume, speed, and safety requirements.

Warehouse with stacker crane

Warehouse with multishuttle or cube storage

Continuous pallet handling

Discontinuous pallet handling

Warehouse

with stacker crane

Warehouse with

multishuttle or

cube storage

Continuous

pallet handling

Discontinuous

pallet handling

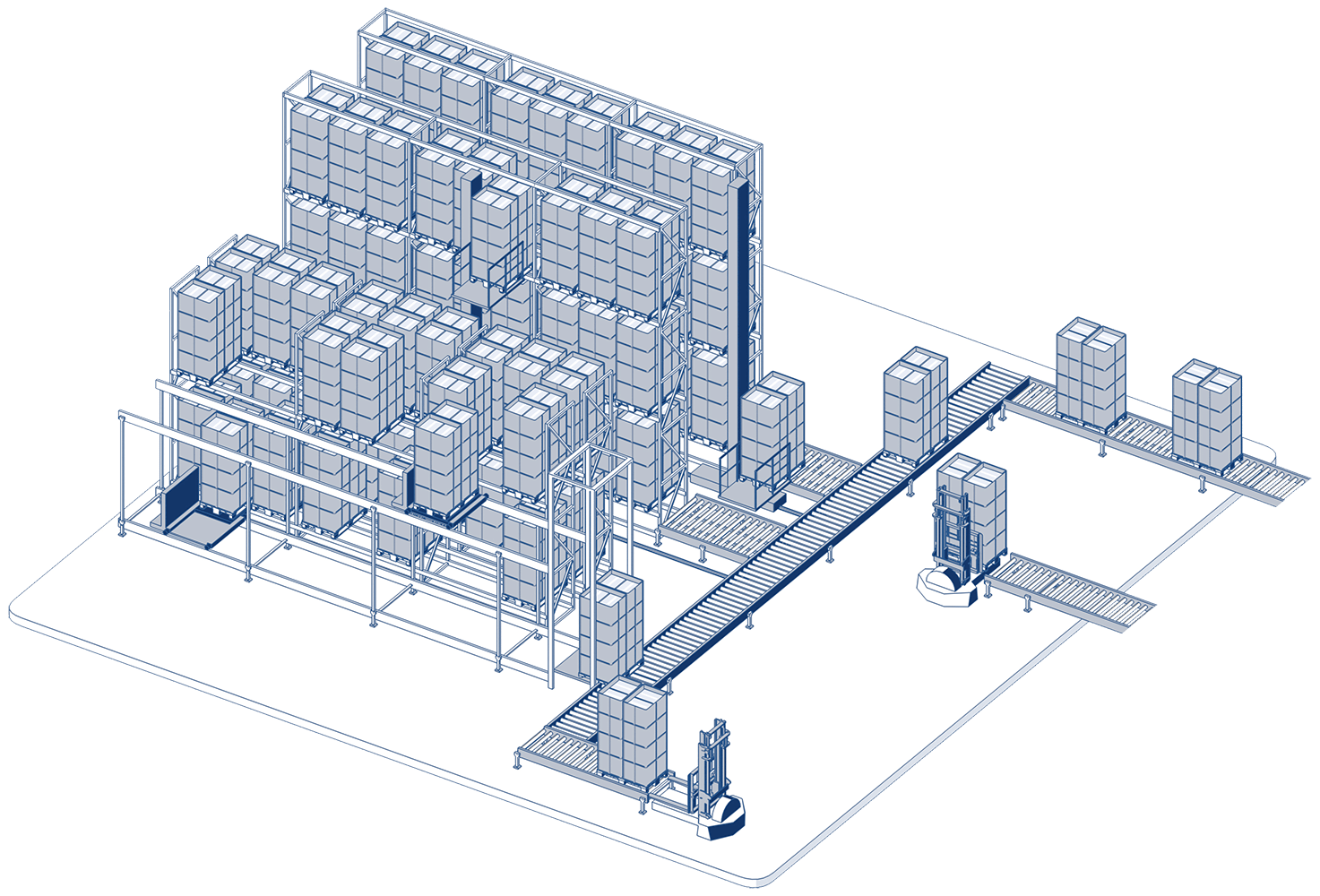

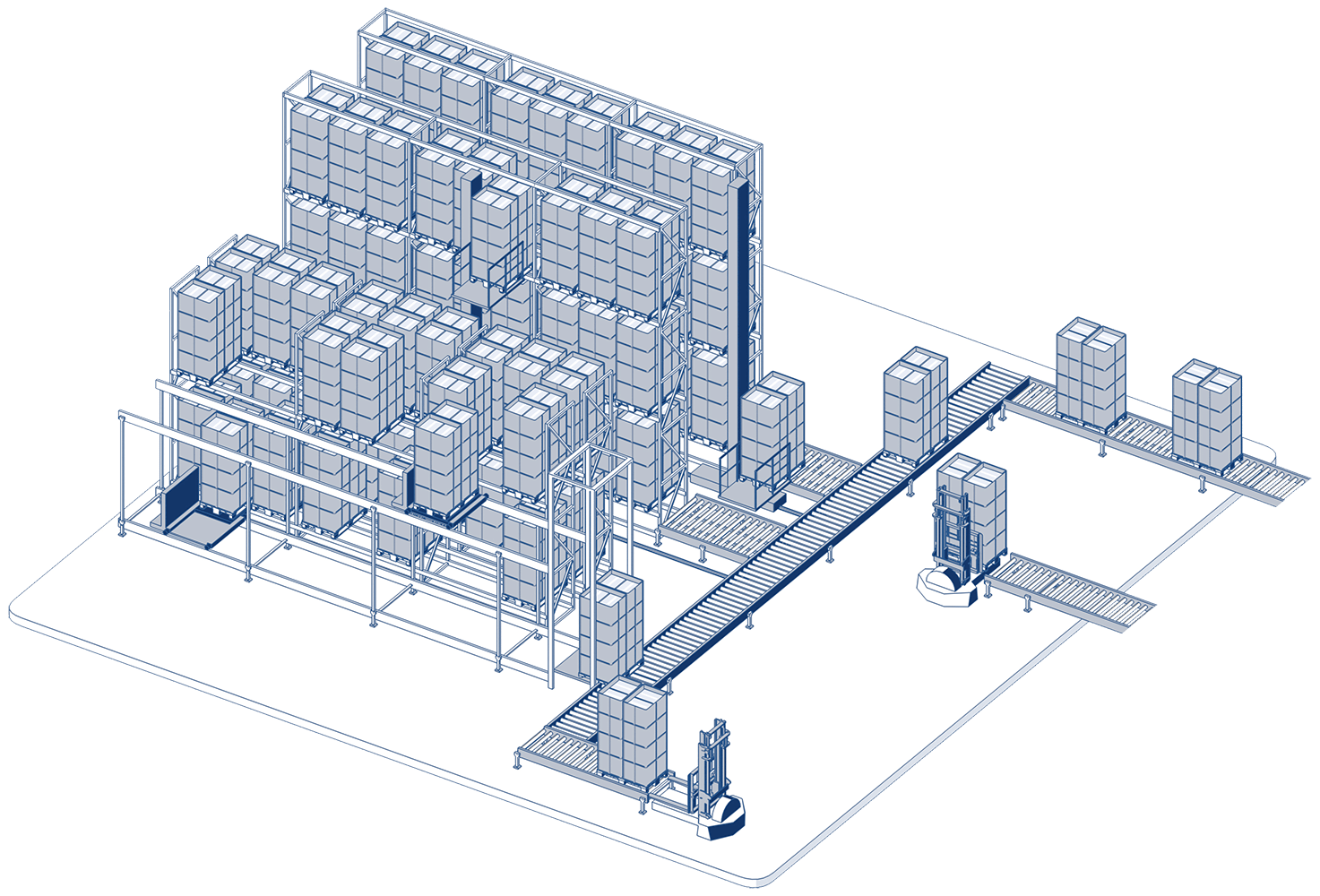

3D Demo Representation with Automated Warehouse and Shuttle System for Pallet Storage

Warehouses with pallet stack cranes

An automated warehouse equipped with stacker cranes for pallets is designed for the storage and automated handling of palletized goods. Stacker cranes (available in single- or double-column frames depending on system requirements) operate within aisles between racks, handling pallets efficiently and precisely. These systems can reach significant heights—up to 45 meters—and are compatible with single or double-depth racking systems.

Case history

AMBROVIT

How Automation Has Transformed the Warehouse into a Center of Logistics Excellence

Warehouses with miniload systems for totes

This type of warehouse is dedicated to the automated storage of goods in boxes or totes. Its key feature is high-speed operation for minimized pick and deposit times. It can be installed within existing structures or in self-supporting warehouses, making the most of available space. The system includes industrial racking, tote-specific stacker cranes, electronic components, and management software. Handling is possible at single, double, or multi-depth levels, depending on logistical needs.

Warehouses with shuttle systems

A shuttle warehouse is an advanced storage and material handling system designed to maximize space optimization. At the core of this system are small robotic vehicles known as shuttles. These vehicles move autonomously along rails, tracks, or a mother structure within the warehouse racking system. Shuttles can pick up and deposit load units—such as pallets, totes, or containers—at different warehouse levels. Their movement can be both horizontal and vertical, assisted by elevators or other semi-autonomous systems. In the case of four-way shuttles, movement is also orthogonal, providing maximum flexibility and efficiency.

Warehouses for special load units

Automated warehouses designed to handle special load units such as fabric bins, coils, sheets, long bodies, vehicle frames, bars, or wooden panels. These systems are customized to move and store goods of non-standard shapes and dimensions, ensuring both efficiency and safety in operations.

Warehouses with overhead cranes

Overhead cranes are machines designed to move very heavy and bulky materials precisely and reliably, both indoors and outdoors. In partnership with Dematic, LCS handles automation and revamping of these technologies, enabling the lifting device (winch or hoist), connected to a beam, to move along horizontal tracks.