The term material handling refers to the movement of materials of various types within industrial environments. It encompasses everything that helps distribute and position materials in the right place and in the correct quantity.

Our handling and sorting solutions ensure fast, safe, and uninterrupted workflows. LCS Group employs technologies such as modular conveyors, capable of handling both light loads (parcels, totes, cartons) and heavy loads (pallets), pick-to-light systems for small parts order fulfillment, and high-speed sorters to efficiently manage large volumes of material—ideal for sectors such as e-commerce, retail, and distribution logistics.

In addition, AGV/AMR systems (Automated Guided Vehicles / Autonomous Mobile Robots) are particularly suitable for material transport in areas shared with operational personnel.

Trasporto leggero

Movimentazione pallet

Smistamento con sorter

Movimentazione con AGV-AMR

Trasporto

leggero

Movimentazione

pallet

Smistamento

con sorter

Movimentazione

con AGV-AMR

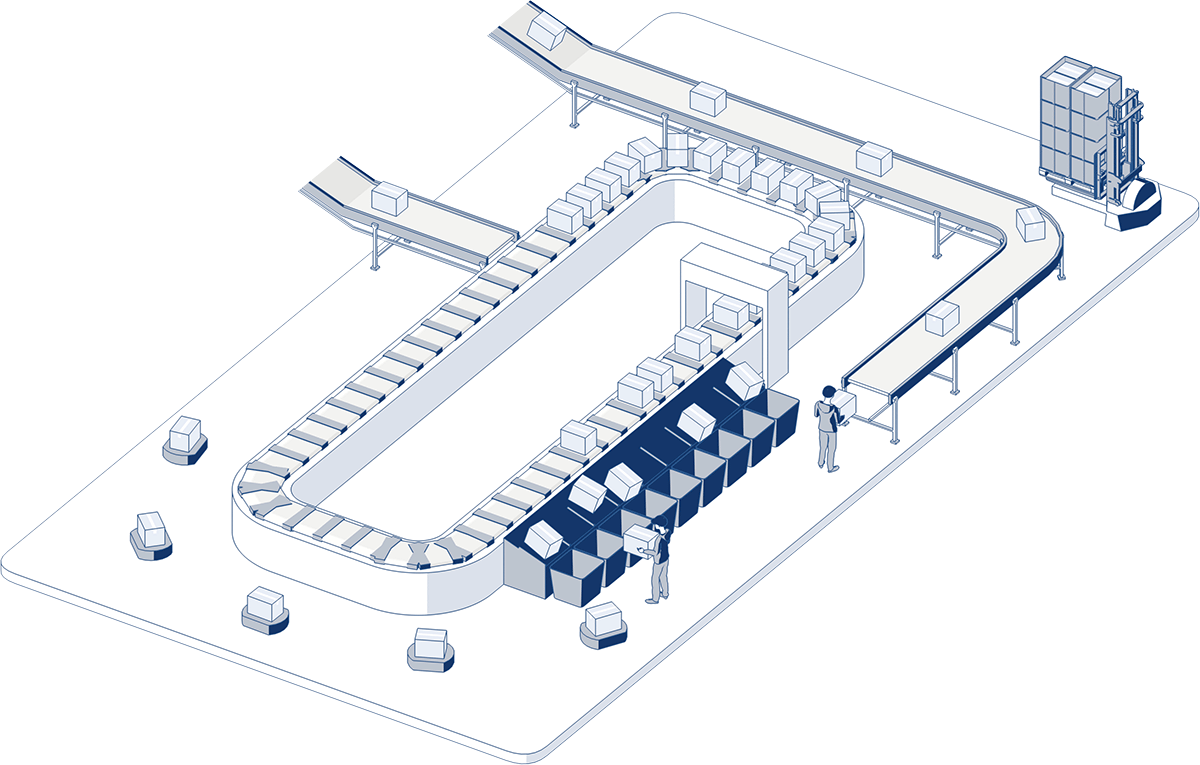

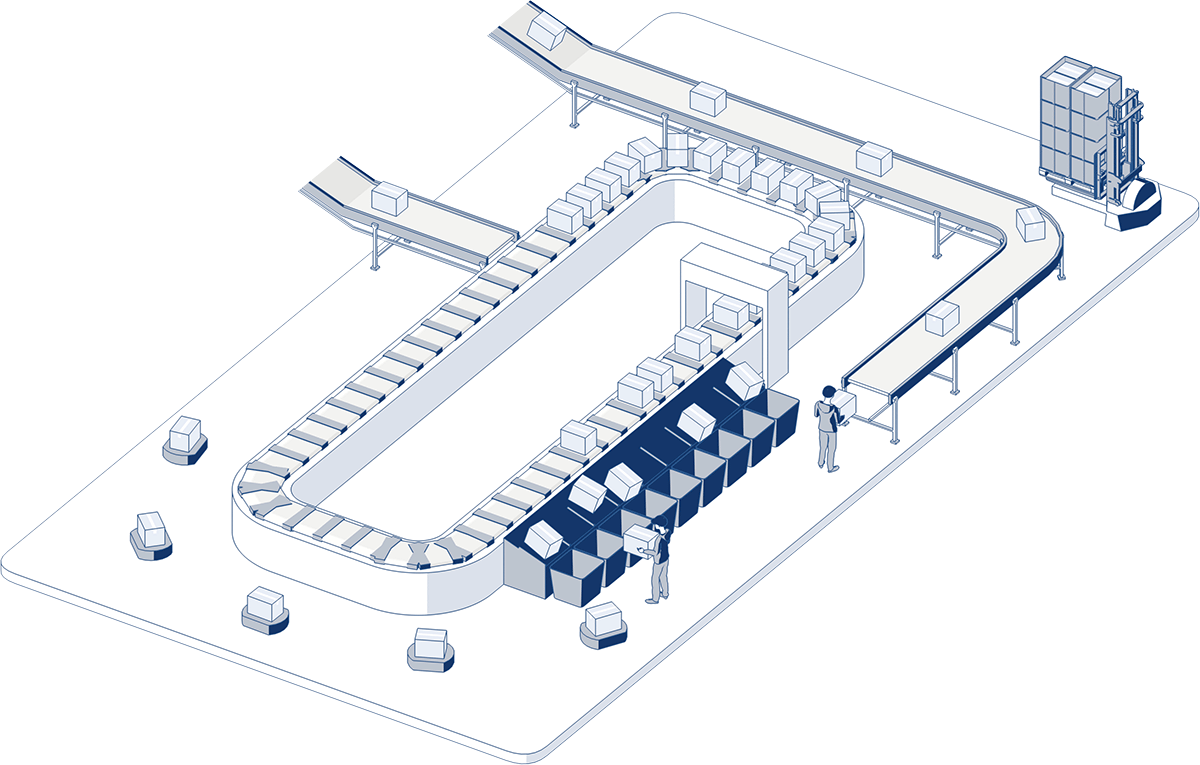

3D Demo Representation: Cross Belt Sorter and AGV-AMR System

Roller or chain conveyors are defined as continuous flow systems, consisting of long conveyor lines. They are ideal for transporting heavy loads such as pallets and bins. Roller conveyors can be either powered or gravity-based: when rollers rotate via an electric motor, they are referred to as motorized roller conveyors, while gravity conveyors rely on slope for movement. Depending on industry requirements, we provide chain conveyors (catenaries) or roller conveyors. With the integration of elevators/descenders, goods can be transferred across multiple levels, while diverters and turntables enable deviations and redirections, completing fully integrated handling solutions.

For light load handling—such as totes, cartons, trays, and other items—we provide conveyor solutions with rollers, belts, and modular chains, made from various materials (e.g., rubber, PVC) depending on sector-specific needs. These continuous flow systems for light loads are widely adopted to improve efficiency and reduce handling times.

Highly modular and adaptable, these solutions are ideal for transporting both single items and packaged goods. With elevators/descenders equipped with conveyors, goods can be moved across different levels, supported by stackers and de-stackers that complete the handling process.

Discover our advanced material handling solutions

Discontinuous transport occurs when goods are moved along programmed routes via automation systems or mobile robots, sometimes equipped with on-board conveyors. The management of fleets of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) requires a centralized Fleet Management System (FMS). This software coordinates and optimizes vehicle operations in real time, assigning tasks, monitoring activities, and ensuring a streamlined workflow. An FMS can manage multi-brand fleets and integrate with plant-level production control systems.

AGVs are automated internal transport systems capable of replicating forklift functions. Within a warehouse, they can handle multiple phases—from inbound to storage to outbound. A key advantage is scalability: fleets can be easily adapted and expanded without structural modifications as workload increases.

AMRs operate autonomously and navigate uncontrolled environments without fixed paths or tracks. Known for their flexibility, AMRs are essential for warehouse and production logistics. They can perform picking, replenishment, and transfer tasks. Depending on the operational model, goods-to-person and shelf-to-person workflows enable the handling of totes, cartons, pallets, racks, and shelving between activity zones.

LGVs are driverless vehicles guided by laser triangulation. They are reliable, fast, and flexible, ensuring maximum efficiency and safety. With 360° obstacle and human detection, LGVs guarantee complete workplace safety while maintaining high performance.

Shuttles, whether rail-mounted or inductively powered, are automated vehicles for horizontal transport between different stations. They enable high-speed transfers, typically connecting automated warehouses with picking and shipping areas. Free from external interference, they deliver superior precision and performance.

Discover our dedicated AGV-AMR Division for fleet management

Sorting in automated warehouses is the process of identifying, classifying, and routing products to the correct destinations within the logistics flow. This is crucial for ensuring speed, accuracy, and efficiency in distribution, shipping, and returns—especially in high-volume industries such as e-commerce and distribution logistics.

Automated sorting systems (sorters) divide goods according to parameters like size, weight, type, or destination, ensuring optimal routing. Among the most effective technologies are high-performance Cross Belt Sorters and Pick-to-Light systems, which accelerate operations, reduce errors, and maximize supply chain efficiency.

Sorters are automated systems used to classify, distribute, and ship packages, as well as manage returns in e-commerce and distribution. A Cross Belt Sorter is an advanced type of sorter that uses transverse belts mounted on mobile carts to divert products to the correct destinations. This technology provides high-speed and high-accuracy sorting, with capacities of up to 25,000 units per hour.

These order picking and kitting support solutions reduce waste and lead times while boosting productivity. Easy to use and paperless, they streamline order fulfillment through visual light signals. By indicating the exact item location and required quantity, pick-to-light systems make warehouse picking faster and more accurate.

Baggage handling is a mission-critical infrastructure in airports, responsible for the automated transport, sorting, and routing of luggage. This process relies on conveyors, sorters, and advanced identification technologies (barcodes, RFID) to ensure traceability and precision.

Integrating high-performance systems such as Cross Belt Sorters ensures smooth and continuous operations, reducing errors, delays, and losses while improving overall airport efficiency.