Robotics

We design and deliver customized Robotic Automation Solutions

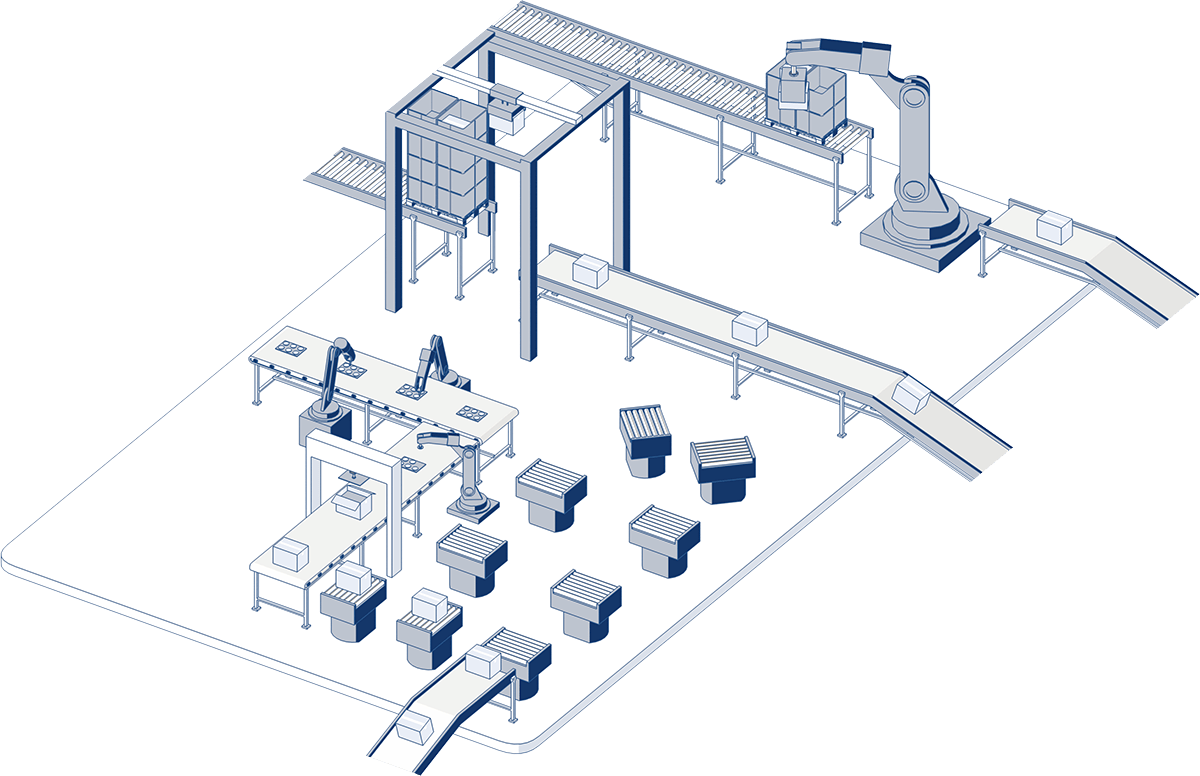

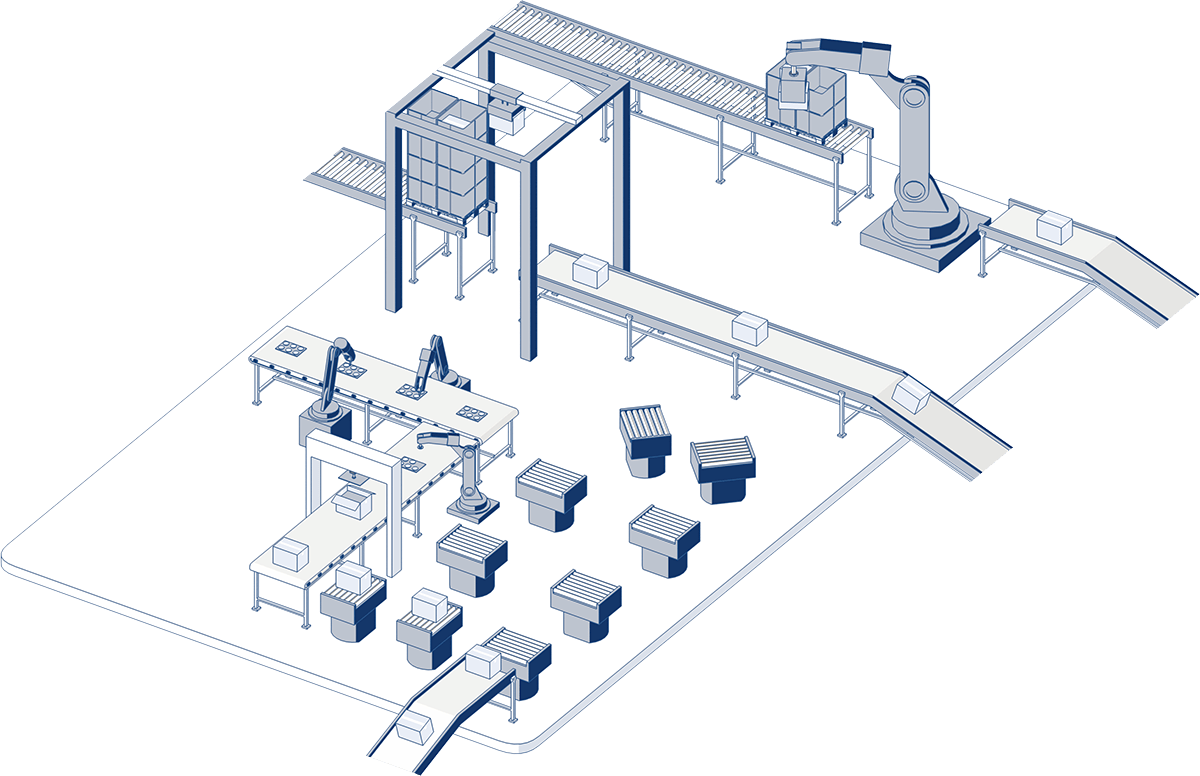

The Robotics Division of LCS Group develops advanced solutions for the automation of production and intralogistics processes.

It integrates robotic systems for palletizing and depalletizing, collaborative robots (cobots) for pick-and-place applications, and robotic islands. Our solutions enhance efficiency, precision, and safety by combining specialized machinery with intelligent devices.

The control architecture includes SCADA (Supervisory Control and Data Acquisition) systems and PLC (Programmable Logic Controllers) for advanced process management.

Islands with Cartesian robots

Anthropomorphic palletisers

Assembly and handling lines

Mobile robot

Islands with

Cartesian robots

Palletisers

anthropomorphic

Assembly and

handling lines

Mobile

robot

3D demo of automated systems for palletizing, depalletizing, and production line feeding

Intralogistics Process Automation

Automating intralogistics processes has become a key factor in improving operational efficiency, increasing productivity, and ensuring accurate control across the entire value chain—from inbound goods receipt to outbound shipments.

Through scalable and modular solutions, every stage of the internal logistics flow can be optimized by integrating semi-automatic and robotic technologies tailored to the specific needs of each facility or customer.

Inbound

The inbound process refers to receiving goods into the warehouse or production plant, which can be managed with different levels of automation:

Semi-automatic

Goods receiving with manual quality control supported by voice systems, RFID, and artificial intelligence platforms for document reading and digitalization.

Robotic

Loading bays equipped with quality-control selectors, automated depalletization, sequencing, and systems for pallet replacement at inbound.

Outbound & Picking

The outbound process manages the dispatch of goods to customers, branches, or other sites. The goal of ensuring accurate, on-time, and fully traceable shipments can be achieved through different levels of technology:

Semi-automatic

Voice picking, barcode/RFID terminals, pick-to-light systems, cross-docking and shipping supported by software solutions.

Robotic

Bin picking, goods-to-person or shelf-to-person systems, palletizing with cartesian or anthropomorphic robots, and automated wrapping and labeling.

Case history

Production Automation & Line Feeding

The efficiency of production processes increasingly relies on automation solutions capable of supporting or replacing manual activities, ensuring continuity, precision, and flexibility.

Production line feeding and material management can now leverage advanced systems that combine semi-automatic and robotic technologies: from AGVs and AMRs for internal transport, to cobots integrated into production lines, up to intelligent systems for component kitting and distribution.

Material Management & Kitting

Efficient material management and kit preparation are strategic to ensure production continuity and minimize setup times and line stoppages.

By integrating semi-automatic and robotic technologies, it is possible to optimize the logic of component picking and delivery, improve operator ergonomics, and guarantee maximum accuracy in assembling kits for production.

Semi-automatic

Put-to-light systems supported by operators with guided software.

Robotic

Robotic systems for kit preparation and material delivery to the production line, as well as automated handling and assembly.

Case history

USAG (TBD)