Skip to content

Salice

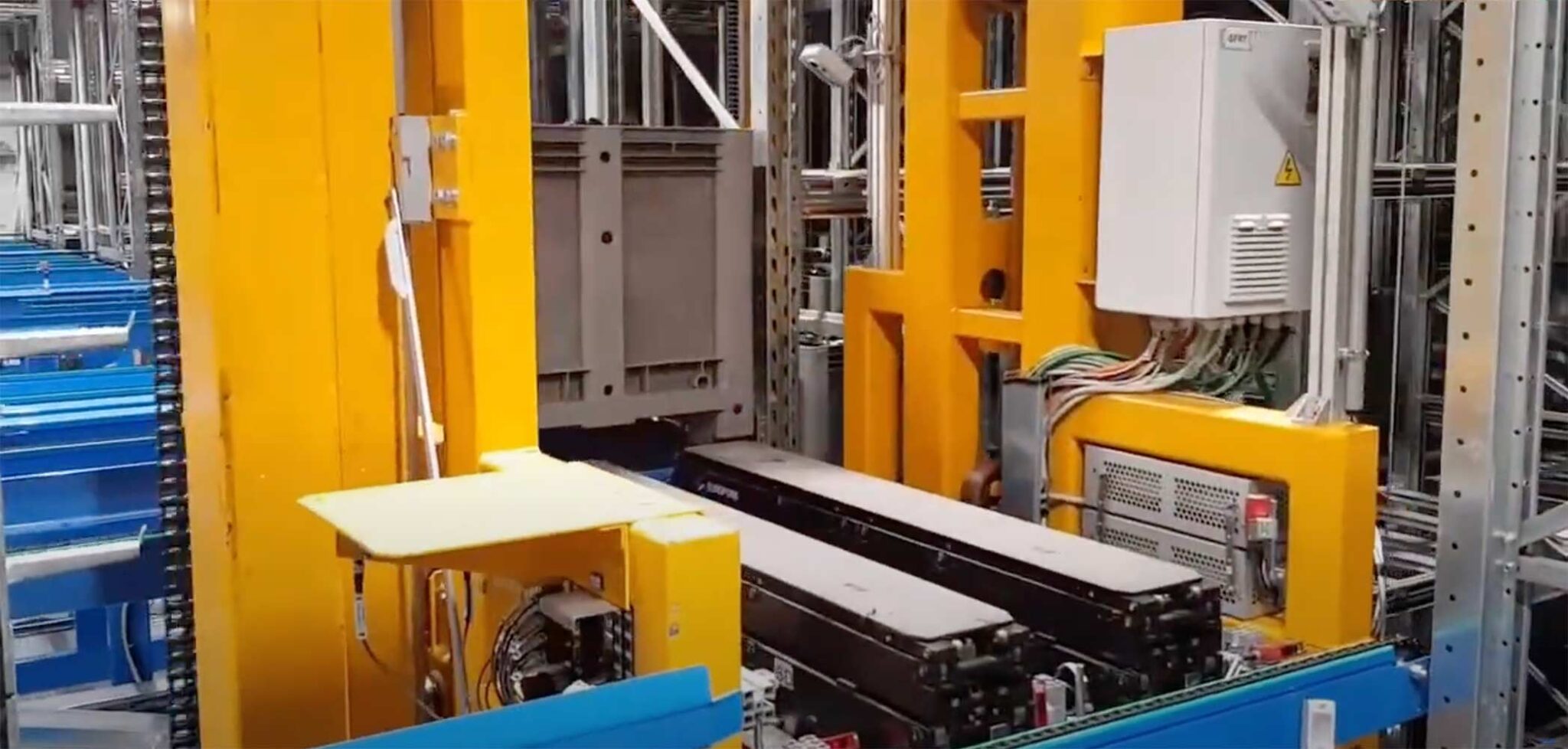

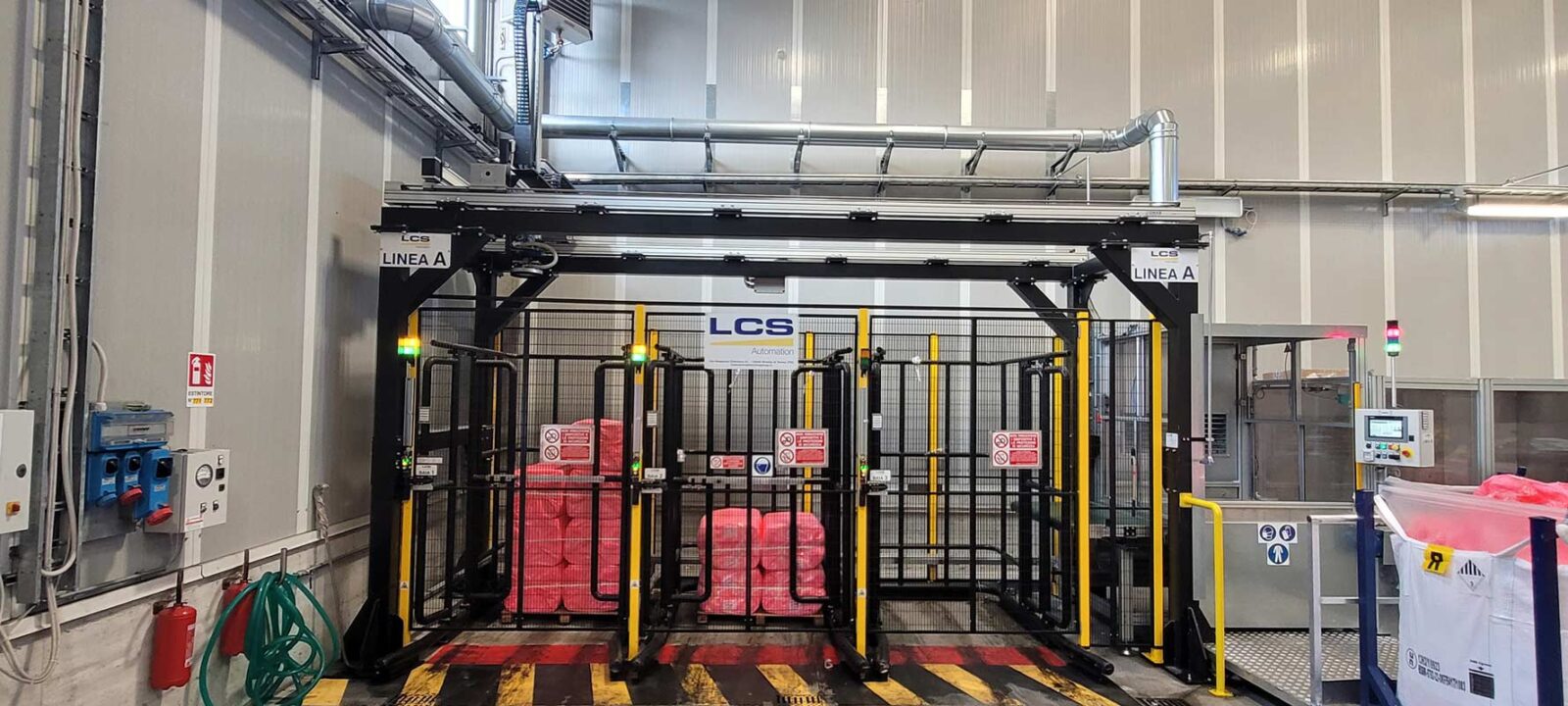

Automatic picking system

Solutions

Material Handling and Sorting

Robotics

revamping

Sector

Manufacturer

Challenge

An old Gantry robot needed to be replaced with a new, more efficient one. The installation took place during the summer shut down. In order to avoid unexpected events during this short period (2 weeks), the system was assembled and tested in LCS before being delivered to the Customer.

Solution

The proposal included the design and construction of an automatic warehouse and material handling system starting from the supply of self-supporting shelving, and included, in addition to mechanical components, the electrical installation for control, and the automation supervision software interfaced with the client’s WMS system.

- Buffer warehouse between the existing automatic warehouse and the picking area

- T-car with hoist to store and retrieve pallets to/from the buffer warehouse

- 4-ways turning table to increase the throughput.

- 4-axis robot on linear unit to pick cartons from a display of 12 full pallets and place them on one of the customer pallets

- Nr. 2 Printer & Apply machines

- Manual picking area

- PLC Software modules LogiTRASP

- PC Software module LogiCON

Key technical data

- Buffer warehouse capacity: 38 pallets on rack + 12 displayed

- Full pallet max dimensions: 800 x 1.200 x (H) 1.350 mm

- Customer pallet max dimensions: 800 x 1.200 x (H) 1.150 mm

- Full pallet max weight: 650 kg

- Boxes/layer: 6

- Throughput: 800 boxes/day