Growermetal

Self-supporting automatic warehouse for an optimized supply chain

Solutions

Automated Warehouse

Material Handling and Sorting

software

Sector

Metallurgical

Challenge

Growermetal, a company specializing in the production of safety lock washers and metal components, has chosen LCS to build a 20-meter-high self-supporting automatic warehouse to optimize the supply chain with a scalable automatic system, increase storage capacity, and improve logistical efficiency.

Solution

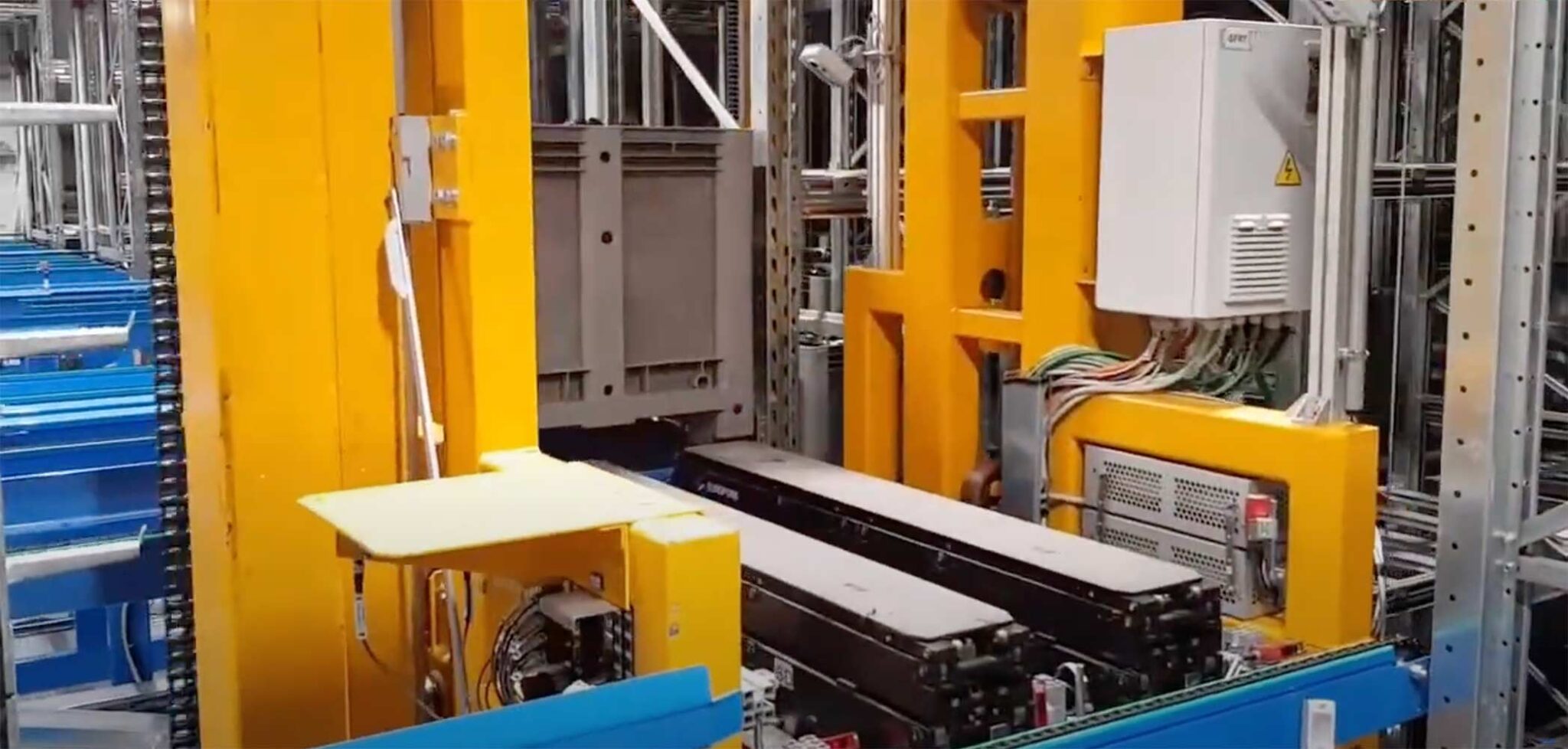

- Self-supporting warehouse with an automated area of 1,500 sqm

- Flexible handling system, with LGVs replacing fixed roller conveyors to allow for future expansions

- Advanced software integration for the management and monitoring of logistics missions

Key technical data

- Storage capacity: 5,493 pallets / 10,986 bins or half-pallets

- Self-supporting height: 20 meters

- Automatic warehouse area: 1,000 sqm

- Stackers: 4

- Daily movements: 850 handling units

- Handling means: 5 laser guided vehicles (LGV)

Full description of the project

Growermetal, an Italian company founded in 1950 and specialized in the production of safety washers, stamped metal parts, and springs for railway applications, has taken a major step forward in logistics by investing in a heavy-duty automated warehouse.

Located in Calco (Lecco), Growermetal employs around 110 people and exports over 80% of its turnover. To optimize its supply chain, the company commissioned LCS to design and implement a 20-meter-high self-supporting warehouse, featuring 17 storage levels and a capacity of up to 5,500 pallet positions or 11,000 bins/half-pallets. The system is powered by four stacker cranes and five laser-guided vehicles (LGVs).

Commissioned in summer 2012 and operational by September 2013, the project was completed in under a year. Designed with future scalability in mind, the warehouse offers high modularity: thanks to LGV integration, productivity can be increased simply by adding vehicles, without altering the existing structure.

The architecture required foundation reinforcement and specialized engineering solutions to support heavy loads—up to 600 kg per load unit—while ensuring long-term stability and safety.

The system supports a fully automated logistics flow:

- Containers from production are loaded at dedicated bays

- LGVs transport them to the warehouse

- Stacker cranes handle storage and retrieval

- LGVs return load units to picking, packaging, and shipping areas as needed

Operations are managed by a dedicated WMS, which plans missions in real time, ensuring precision and minimizing human error.

The system currently handles around 850 missions per day in a single shift, with a saturation level of 50%, leaving ample room for growth. The flexibility of LGVs allows for scalable productivity without structural changes.

For Growermetal, this solution represents a qualitative leap:

- Enhanced material handling efficiency

- Elimination of errors

- Improved customer service

- Optimized human resource allocation

The result is a streamlined logistics system, designed to support dynamic production, ensure fast operations, and provide a solid foundation for future growth.