Ceva Logistics

Advanced automation for cosmetic logistics

Solutions

Material Handling and Sorting

Robotics

software

Sector

3PL

Challenge

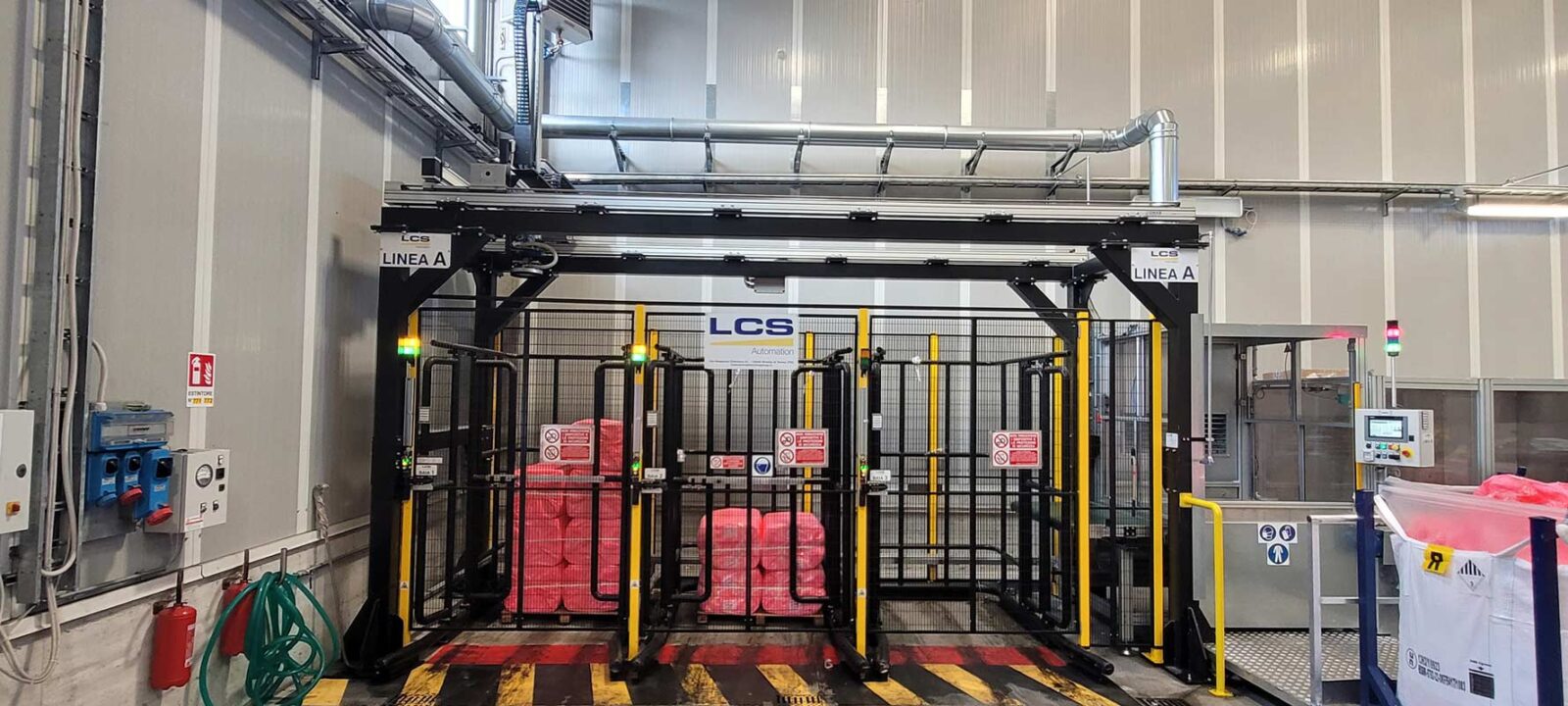

For Kiko’s logistics center in the Milan area, Ceva Logistics tasked LCS with designing a comprehensive intralogistics solution capable of automating and streamlining the entire order fulfillment process to manage up to 400 orders simultaneously, covering: automatic case forming; packing and closing; labeling and final palletizing. All operations had to be integrated into a continuous, accurate flow, with the ability to consolidate up to 10,000 units per hour, while handling a highly diverse mix of cosmetic items—from very small to mid-sized packages—under increasingly tight delivery timeframes.

Solution

To meet this complex need, LCS developed a complete solution centered on a loop cross-belt automatic sorting system, fully integrated with LCS’s proprietary control software.

The implemented platform enabled:

- full automation of the order consolidation process

- optimized handling of high-volume throughput

- reduced operational errors and overall improved efficiency

Thanks to the combination of cutting-edge hardware and intelligent software, Ceva now benefits from a highly reliable and high-performance system.

Key technical data

- 150-meter loop cross-belt sorter

- 200 sort destinations mapped to 400 final destinations

- 2 five-sided scanner systems capable of reading 1D/2D barcodes and detecting parcel volume

- Two systems for the overhead transport of empty boxes

- A conveyor system for item transport, featuring three palletizing stations for shipping

- 2 induction zones:

- 1 automatic area with 3 induction lines

- 1 manual area supporting 6 operators