Cartiere del Garda

Automated Warehouse Revamping

Solutions

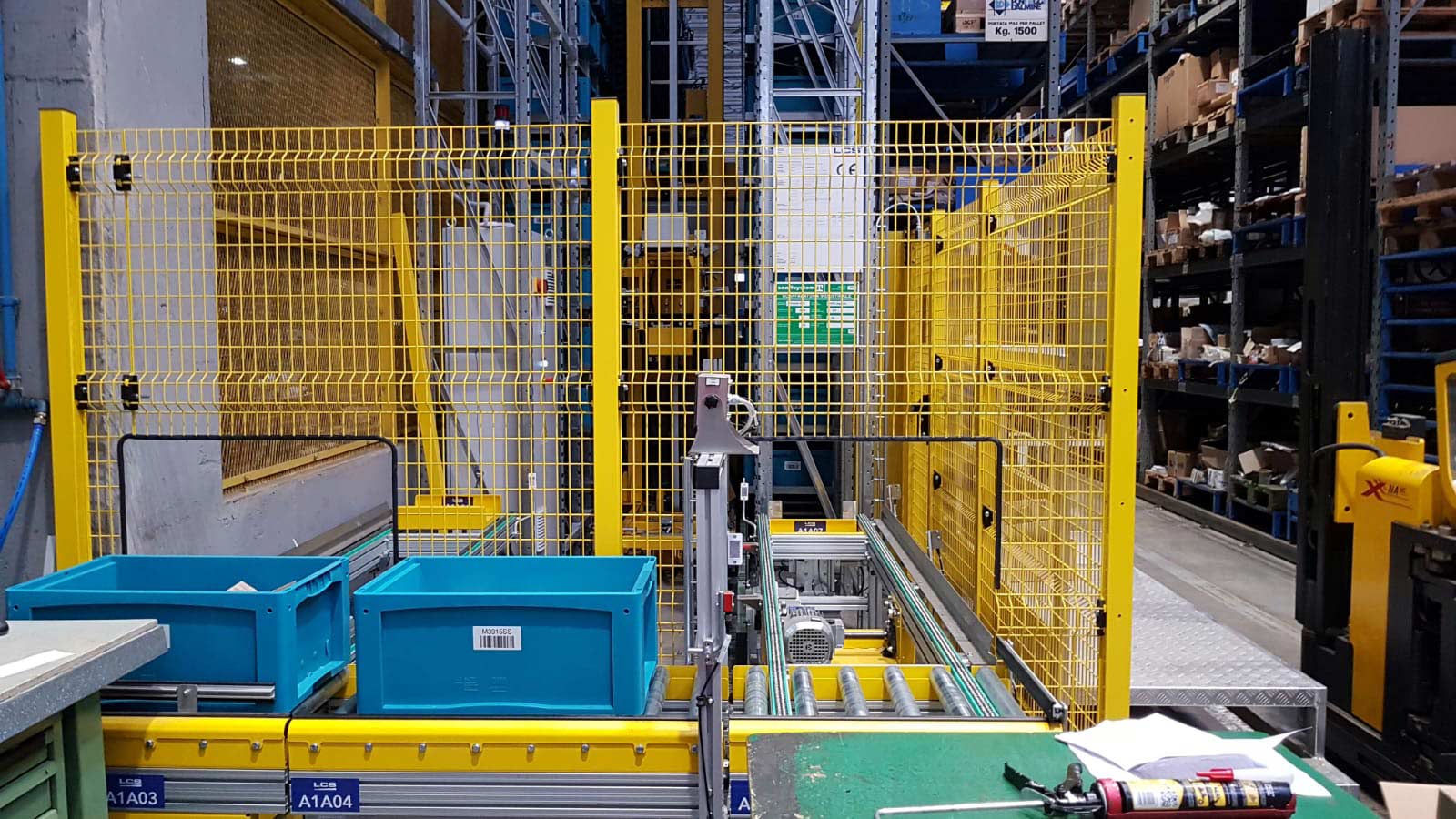

Automated Warehouse

software

revamping

Sector

GENERAL INDUSTRY

Challenge

Cartiere del Garda, a coated paper supply chain, needed a solution to reduce failures and improve the accuracy of its automated reel warehouse without disrupting production.

Solution

- Technical upgrades

- Installation of WMS and WCS software

- Implementation of a real-time monitoring system

- Wi-Fi communication system

- Replacement of worn-out components

- Refurbishment of plant systems and climate control

- Motor replacement

- Power supply conversion from 500V to 400V

- Installation of surveillance cameras

- Replacement of wired communication systems with wireless devices

- Redesign of laser detection systems

Key technical data

- Increased cycles per hour: from 35 to 45

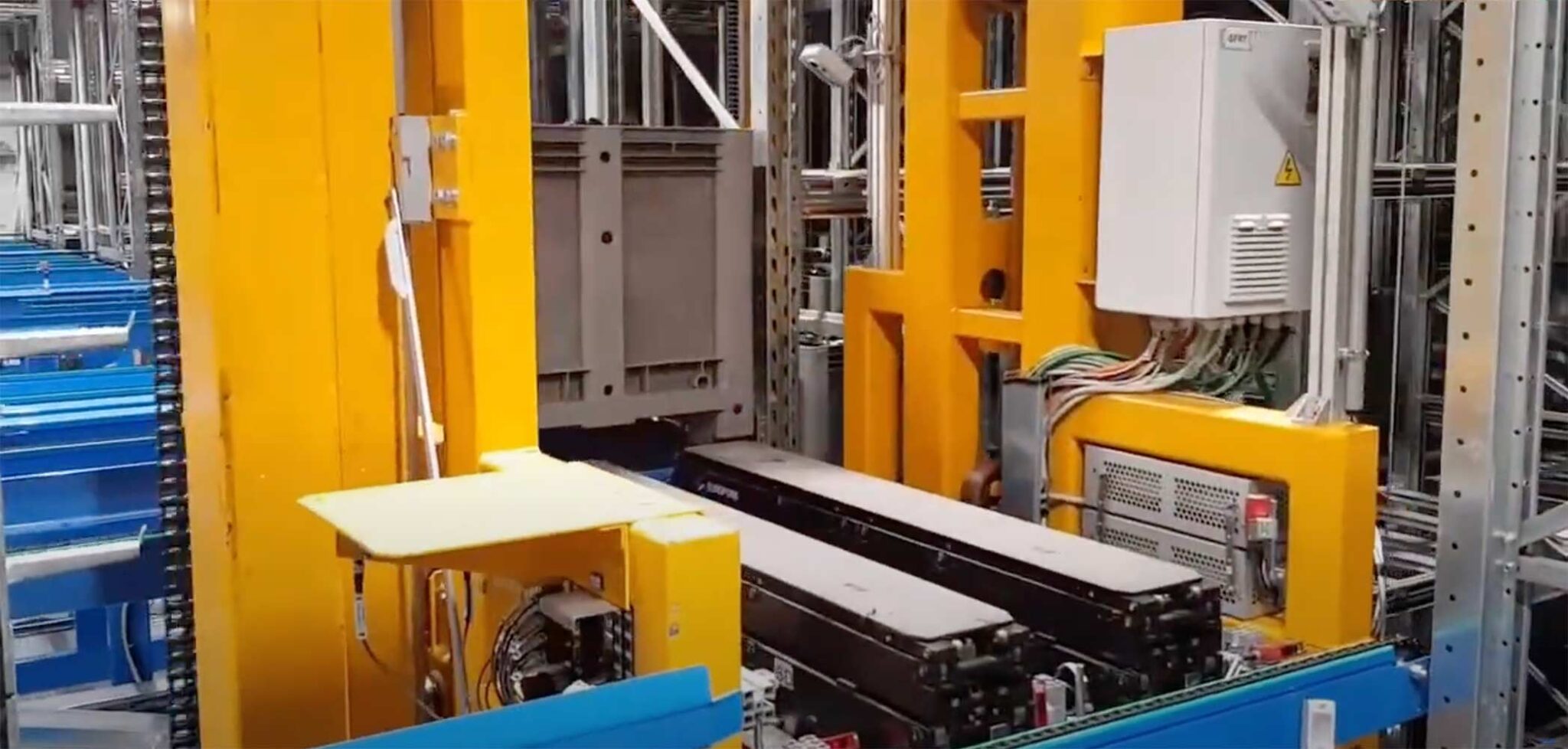

- Automated warehouse managed by an automated crane

- Real-time monitoring system

- Wireless communication

- Enhanced safety category to PL (Performance Level – EN ISO 13849-1)

Full description of the project

Cartiere del Garda, a renowned Italian company specialized in the production of coated paper, has recently undertaken an ambitious automated warehouse revamping project, relying on the expertise of LCS to carry out a complex intervention within an extremely tight timeframe.

Located in Riva del Garda, the company operates 365 days a year, handling a delicate product like paper, and could not afford a prolonged production halt or a complete emptying of its automated warehouse, where paper reels are handled by an overhead automatic crane.

The intervention had to be executed “on the fly,” inspired by the Formula One pit-stop philosophy, during a scheduled technical break in August—a period when a precisely planned production pause would cause minimal disruption.

The project began with the order received in April 2015, followed by preparations starting in January 2016, and culminated in the go-live in August of the same year. The entire operation was meticulously planned, with a detailed timeline of interlocked actions, rehearsed step-by-step with the on-site team to ensure flawless execution.

LCS delivered a comprehensive upgrade of the system, both mechanically and software-wise, to enhance efficiency and safety. Key interventions included:

- Technical modernization of the system

- Installation of WMS and WCS software

- Implementation of a real-time monitoring system

- Replacement of outdated wired communication systems with wireless devices

- Redesign of the laser detection system, enabling precision within a few centimeters

The available time for the entire operation was just ten days, during which LCS:

- Replaced worn components

- Upgraded the mechanical systems and climate control

- Switched all motors, adjusting power supply from 500V to 400V

- Installed a network of surveillance cameras

- Deployed the new management and control software

All of this was accomplished without emptying the warehouse, keeping the paper reels in place and ensuring continuous operational readiness.

Thanks to this intervention, Cartiere del Garda achieved a major technological leap, with tangible benefits including:

- Increased system availability

- Enhanced warehouse performance

- A throughput boost from 35 to 45 cycles/hour

- An upgrade in safety category level to PL

Executed with Swiss precision and Italian heart, the project enabled the company to further improve its performance and solidify its position as a benchmark in coated paper manufacturing.