Eco + Eco

Waste pit filling and hopper feeding management for a waste-to-energy plant

Solutions

Automated Warehouse

software

revamping

Sector

GENERAL INDUSTRY

Challenge

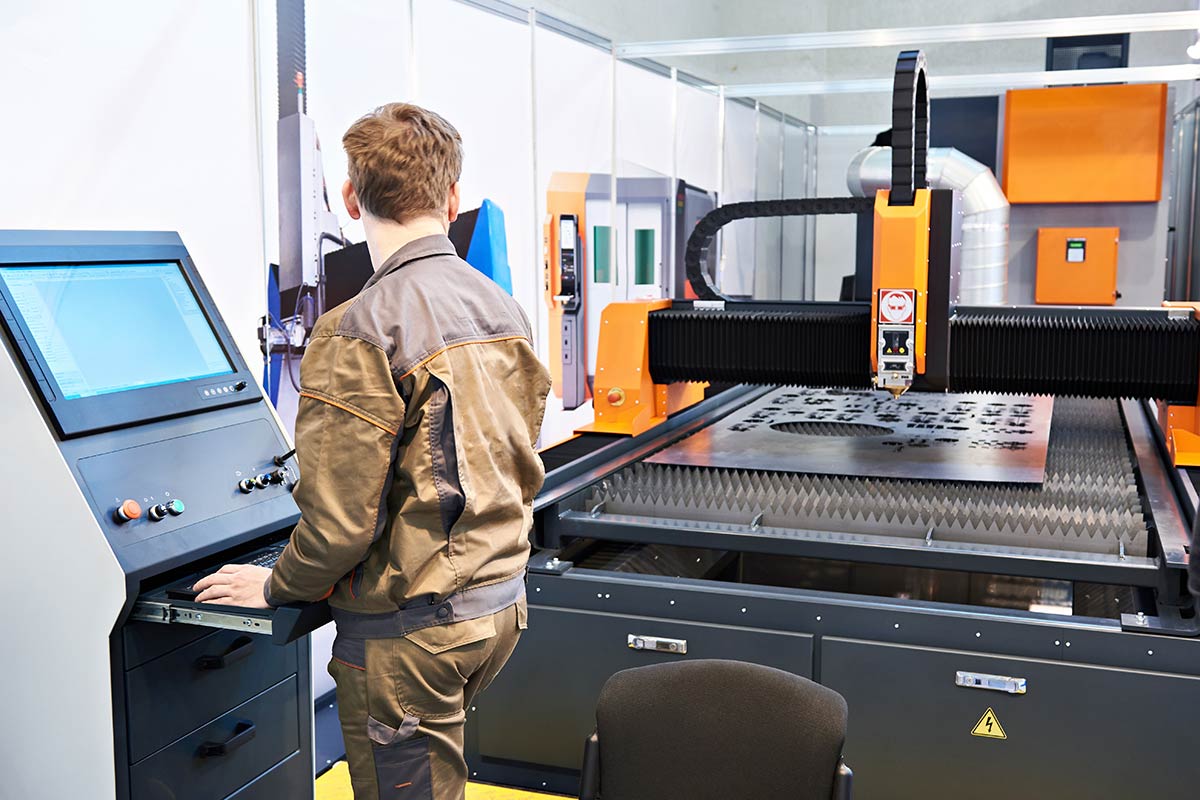

Client: ECO+ECO, responsible for the management of dry waste for the Municipality of Venice. Waste is transported to the treatment facility by specialized trucks that unload their contents into a large containment pit. Overhead cranes are used to load the hoppers by retrieving waste from the pit; The revamping project aimed to modernize the crane automation system, enabling continuous monitoring of filling levels and ensuring safe areas during truck unloading and pit filling operations; This had to be implemented within a complex and dynamic industrial environment.

Solution

- The proposed solution involved the design and implementation of a system revamp, migrating from Profibus to Profinet technology, and the automation of the two overhead cranes to manage the following operations:

- Filling of hoppers for feeding the waste-to-energy plant

- Filling of the waste pit

- Safe area management during truck unloading operations into the pitBackup functionality in case one crane is out of service due to maintenance

The solution required management of safe positions using optical encoders with QR code reading, specifically designed for heavy-duty environments.

The entire system is orchestrated by our proprietary software LogiMHS and LogiCrane, which handle field data acquisition and execute decision-making processes to optimize material flows and ensure continuous hopper feeding.

Key technical data

- Crane capacity: 9 tons

- Height from pit bottom: approx. 20 meters

- Aisles: 1 aisle with 2 overhead cranes operating on the same runway

- Aisle length: approx. 70 meters

- System productivity: 24/7 continuous operation

- Monitored and managed hopper filling points: 4 hoppers

- Managed truck unloading gates: 9 gates with signal lights for access authorization