Kuehne + Nagel

Revamping and expansion of the automatic spare parts warehouse

Solutions

Automated Warehouse

Robotics

software

revamping

Sector

3PL

Challenge

The Iveco automatic spare parts warehouse in Turin, built in 1997, needed a technological upgrade to meet new operational requirements and the increase in daily shipments. It was essential to improve storage capacity and efficiency without interrupting the workflow.

Solution

- Software renewal: updating the PLC, WMS, and WCS to optimize automated warehouse management.

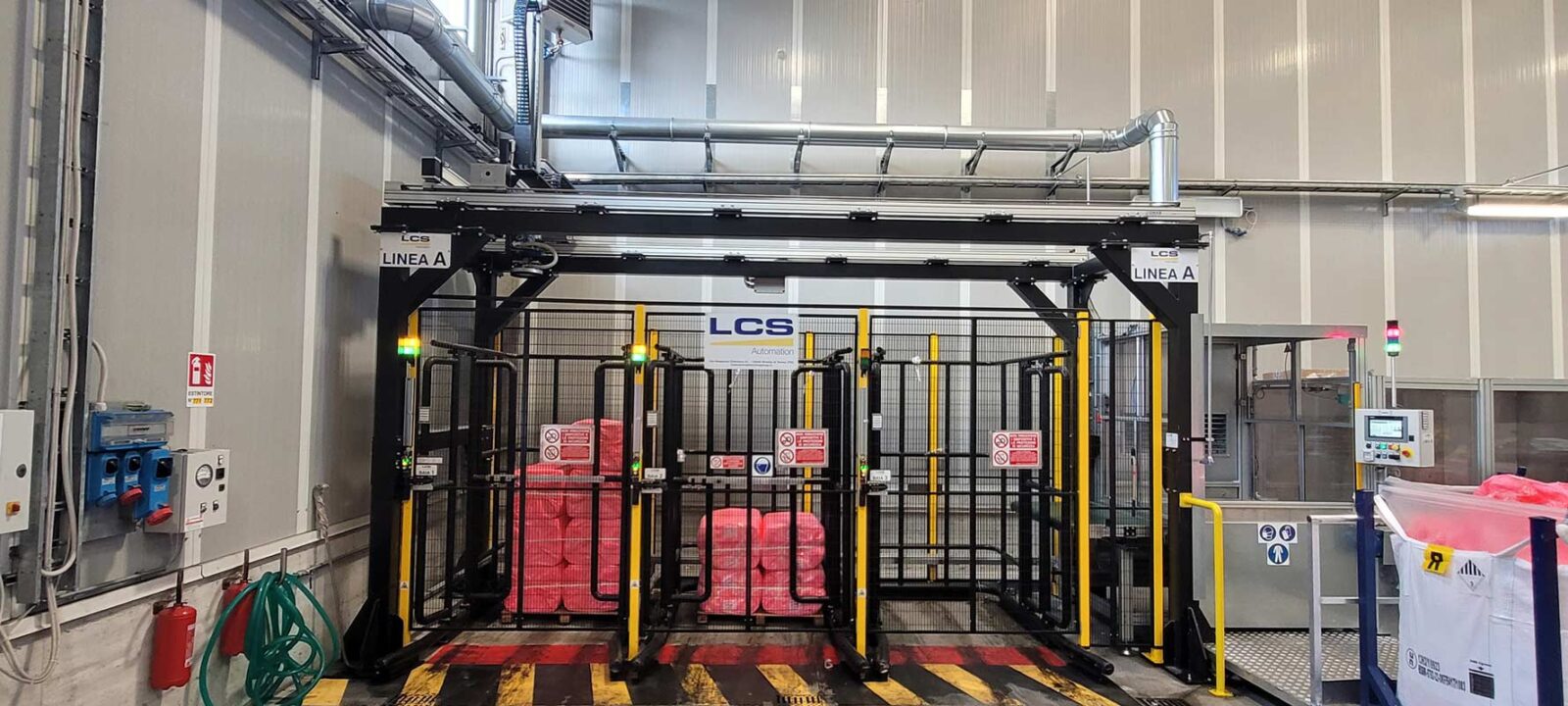

- Storage system expansion: installation of 2 Kardex Mlog miniload stacker cranes with telescopic forks for double-depth storage.

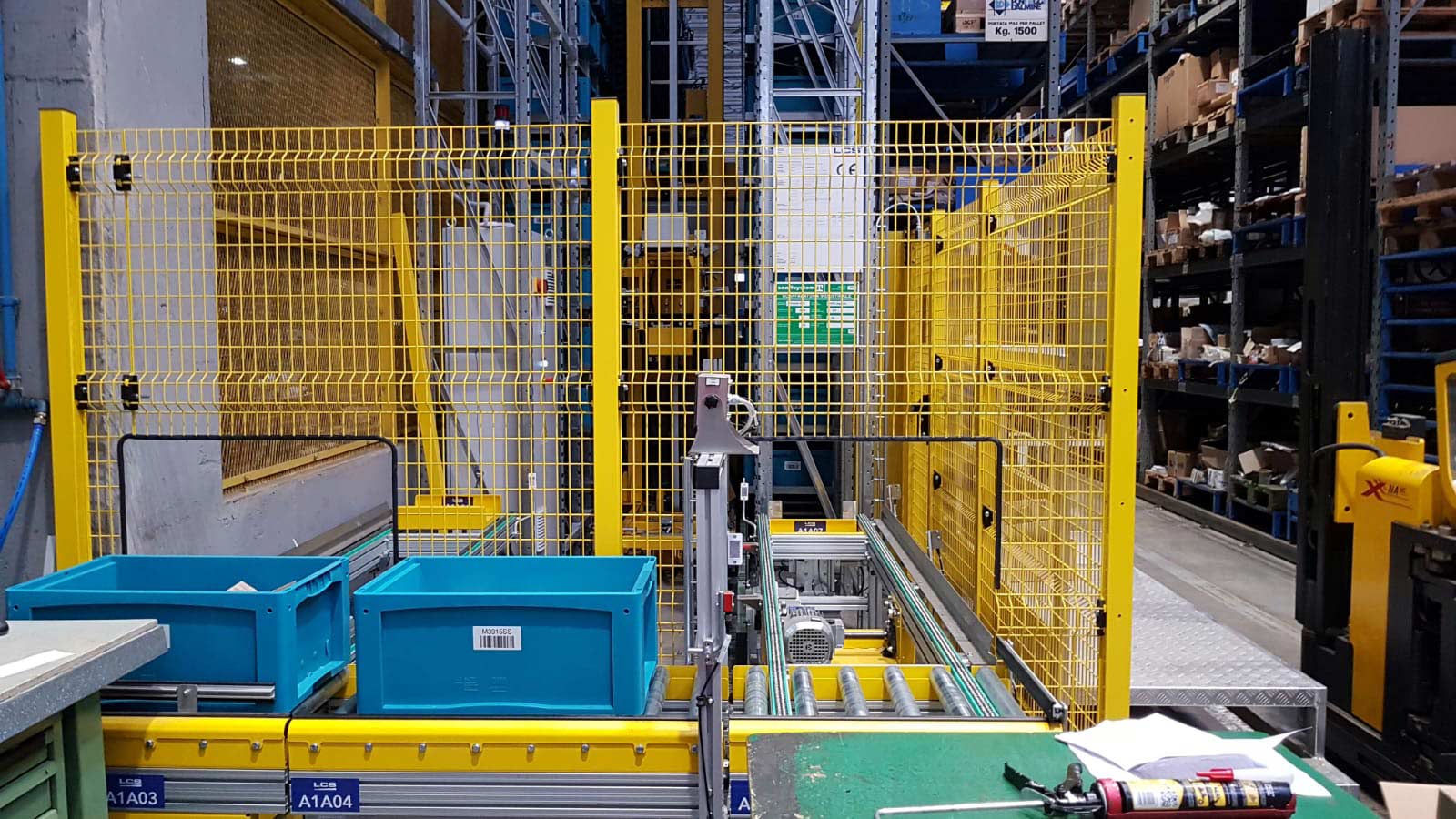

- Handling improvement: implementation of a new two-level head for connecting existing and new storage areas.

- Picking and entry bays optimization: reconfiguration of picking stations to increase order fulfillment speed.

- Training and support: assisting operators with training sessions and post-intervention support.

Key technical data

- 4 stacker cranes with three gripping devices each for Odette-type bins (40x60xH30, max 50 Kg)

- Aisle length: 150 meters

- Stacker crane height: 10 meters

- Static capacity: approximately 45,000 bins

- 12 single-order picking bays

- 4 shipping preparation bays

- PLC software “LogiTraslo” and “LogiTrasp,” WCS visualization and supervision software “LogiCon,” and WMS management software for the automatic warehouse “LogiWare”

Full description of the project

The revamping and expansion project carried out by LCS for the K+N–Iveco spare parts automated warehouse in Turin is a concrete example of how technological innovation can modernize existing infrastructure and adapt it to evolving market demands.

Originally built in 1997, the facility was designed according to the logistics standards of the time. Over the years, it has been progressively upgraded to handle:

- Increased order volumes

- Higher line counts per order

- Faster fulfillment speeds required by online distribution

Thanks to the partnership with Kuehne + Nagel, a global logistics leader, LCS executed mechanical, software, and infrastructure upgrades without interrupting daily operations.

Key Milestones:

- 2008–2009: Control systems were renewed, including PLCs, WMS, and WCS, improving efficiency and management of Odette bins

- 2010–2011: Two new aisles were added, equipped with stacker cranes and updated handling systems, increasing dynamic capacity and optimizing inbound and picking bays

- Each upgrade was delivered turnkey, including cabling, motorization, software, and compliance integration

2019 Expansion:

- Two Kardex Mlog miniload stacker cranes were added, each with three telescopic forks

- Static capacity was expanded with 37,500 additional bins

- A two-level head-end with roller conveyors and diverters was built to connect the new system with existing aisles, ensuring seamless integration and uninterrupted operations

Alongside mechanical upgrades, LCS delivered:

- A full update of the LogiTraslo automation software

- A new LogiCon supervision system

- Enhanced warehouse management via LogiWare WMS

All interventions were executed without halting warehouse operations, thanks to rigorous coordination and continuous presence of project managers. Upon completion, comprehensive training was provided to operational and maintenance staff, ensuring smooth adoption and effective knowledge transfer.

Results:

- Higher order volume capacity

- Faster fulfillment times

- Improved precision and traceability

- Reduced downtime

- Enhanced responsiveness to K+N–Iveco’s evolving logistics needs

The upgraded warehouse is now a strategic asset in modern logistics, capable of supporting future growth and maintaining high performance, reliability, and operational continuity.