Ambrovit

How automation transformed the warehouse into a Logistics Excellence Center

Solutions

Automated Warehouse

Material Handling and Sorting

software

Sector

Distribution & e-commerce

Challenge

Managing growth that made the old warehouse space insufficient, forcing the company to outsource some activities and seek a solution that ensured greater efficiency.

Solution

- Warehouse: 4+4 stackers 24 meters high + 8 stackers

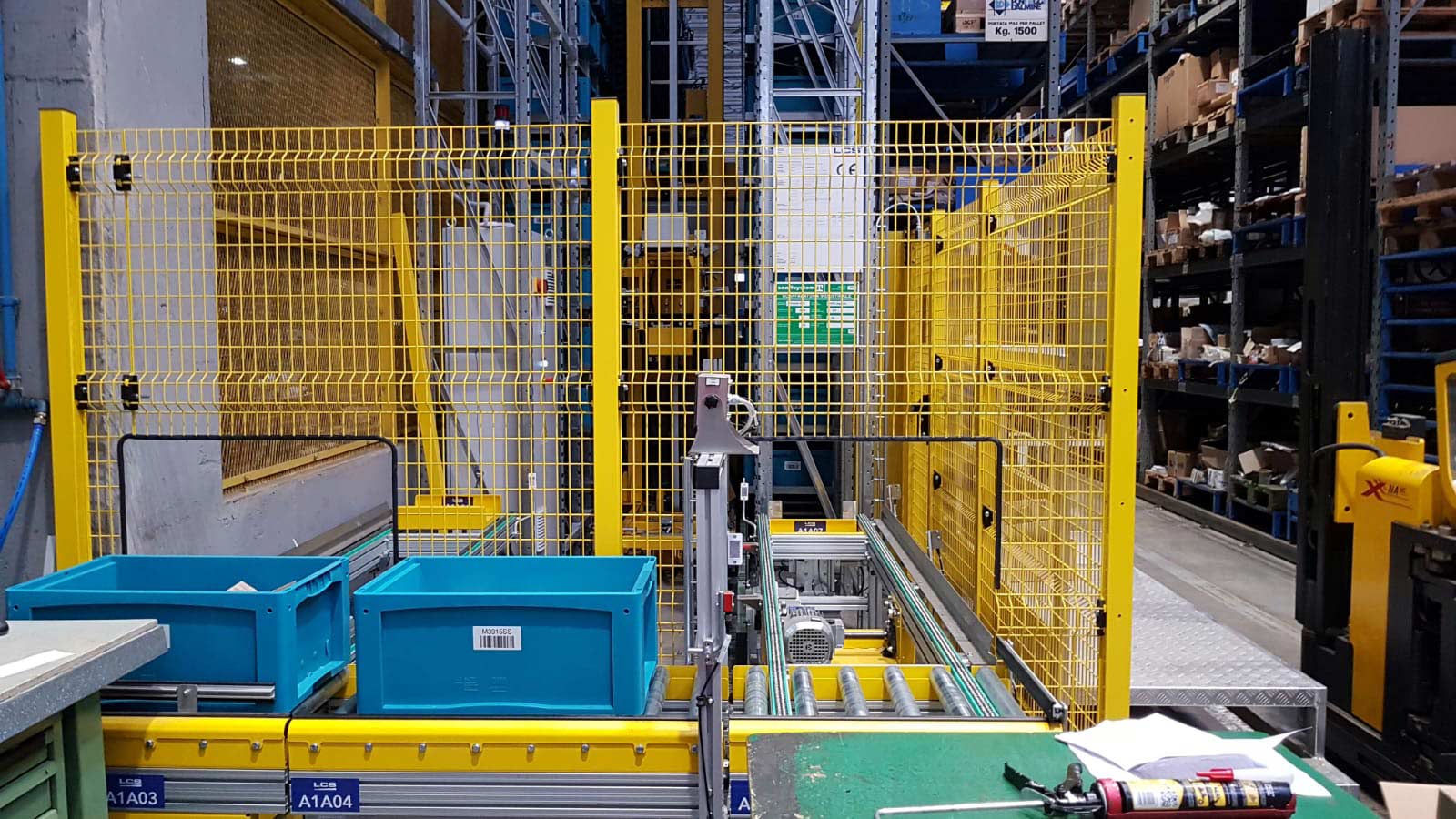

- Operational efficiency: 4+4 picking bays

- Connectivity with the old warehouse through overlapping roller conveyors and elevators/lowerators

- Optimized management: WMS LogiWARE and WCS LogiCON software for automated management and integration with the company ERP

- Miload trays for small-quantity picking

- Inbound pallet buffer warehouse

- Pallet buffer warehouse for picking area

- Pallet buffer warehouse for shipping area

Key technical data

- Warehouse area: approximately 8,000 sqm

- Maximum stock quantity: 100,000 pallet positions

- Picking stations: 8 bays

Full description of the project

Founded in 1997, Ambrovit is now one of Europe’s leading players in the fasteners industry, specializing in the production and distribution of screws, bolts, washers, and fastening components. To meet the growing demands of international customers and respond efficiently to market expansion, the company has launched a major logistics transformation project.

With a catalog of over 12,000 active SKUs, featuring a wide range of shapes, materials, and sizes, Ambrovit faced the challenge of managing a highly complex logistics operation requiring absolute precision, fast order fulfillment, and optimized storage organization.

To centralize and enhance its logistics capabilities, Ambrovit built an innovative automated warehouse at its headquarters in Garlasco (Pavia), in collaboration with LCS and technology partner Kardex Mlog.

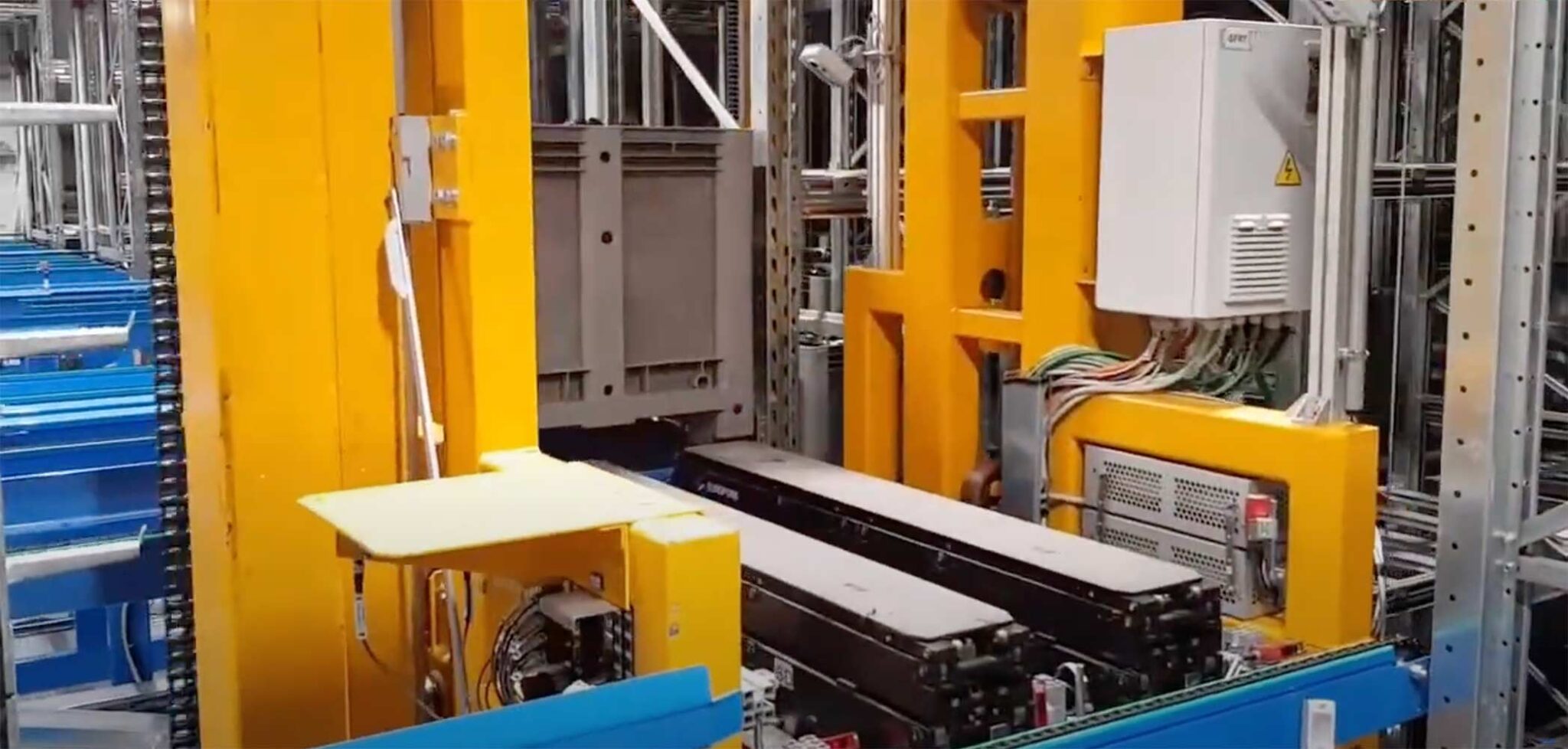

The result is a high-performance self-supporting structure covering 2,000 square meters and reaching a height of 24 meters. At the heart of the system are four automated stacker cranes, designed to handle single-reference europallets, each corresponding to a specific product variant. The system manages approximately 10,000 product codes, ensuring maximum accuracy in storage and retrieval operations.

The warehouse features dual-level operational zones, designed to separate inbound and outbound flows, improving process fluidity and significantly reducing operational lead times.

This new logistics setup has delivered substantial benefits in terms of storage capacity and efficiency. By centralizing logistics flows, Ambrovit has eliminated the need for external or outsourced warehouses, gaining full control over every phase of the logistics process.

Automation has drastically reduced errors associated with manual handling, improved service quality, and ensured faster, more reliable delivery times. Operator working conditions have also improved: goods are delivered directly to ergonomic picking stations, eliminating long internal movements and creating a safer, more productive work environment.

All processes are fully integrated with Ambrovit’s enterprise management system, enabling real-time monitoring of inventory, operations, and warehouse performance. This allows for timely, data-driven strategic decisions based on accurate and up-to-date information.

Ongoing support from LCS ensures the system remains efficient, high-performing, and adaptable to future needs, providing Ambrovit with a lasting competitive edge.

Thanks to this major investment in automation and innovation, Ambrovit has further strengthened its position in the fasteners market, demonstrating how strategically designed logistics can become a true growth engine and a key factor in long-term competitiveness.