Cimberio

Cimberio’s new Smart Factory

Solutions

Automated Warehouse

Material Handling and Sorting

software

Sector

Manufacturer

Challenge

Cimberio, a leader in the production of brass valves and components, required a new warehouse to increase storage capacity, digitize and optimize production and logistics processes, and free up space for new production islands and offices.

Solution

- Greenfield design and construction of an automated warehouse

- 14-meter-high self-supporting structure

- 6 aisles with stacker cranes for metal bins, euro pallets, and half pallets

- Double-deep storage for bins and half pallets, single-deep for pallets

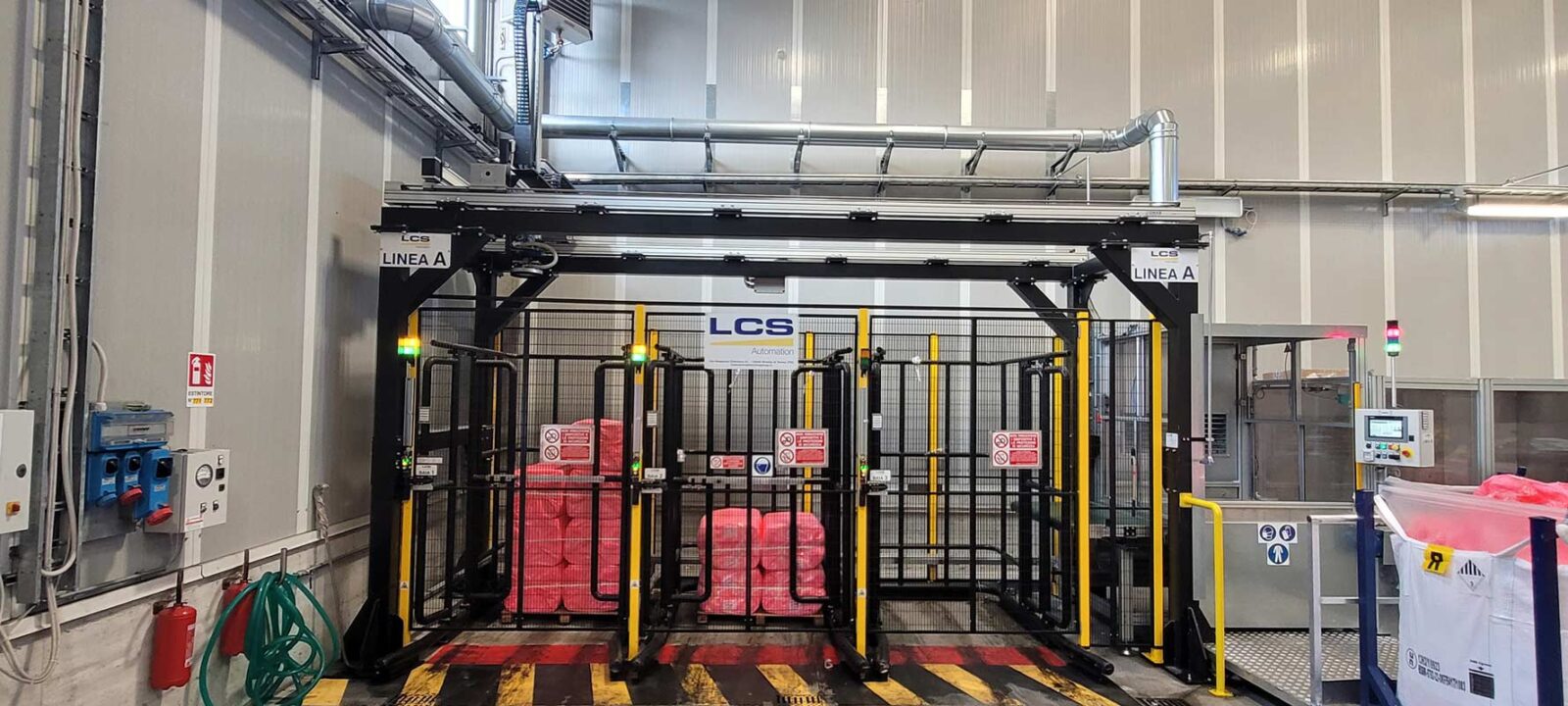

- 5 laser-guided LGVs for inbound and outbound goods handling

- Receiving area with dimension and weight control

- Custom WMS for warehouse management

- MES (Manufacturing Execution System) for production management

- Direct connection to the company ERP

Key technical data

- 14,400 storage locations

- Load capacity: up to 600 kg for metal bins, 1 ton for euro pallets

- 6 aisles with stacker cranes

- 5 laser-guided LGVs

- WMS and MES software interfaced with the ERP

- Dimension and weight control in the receiving area

Full description of the project

Cimberio, a historic company founded in 1957 and a global leader in the production of brass valves and components for hydraulic systems, HVAC, gas distribution, and waterworks, has launched an ambitious digital transformation project in partnership with LCS, aimed at creating a new Smart Factory 4.0 at its headquarters in San Maurizio d’Opaglio (NO).

With a daily output of over 100,000 pieces and a presence in 77 countries through six international subsidiaries, Cimberio invested in a state-of-the-art facility to support growth and improve operational efficiency.

The project involved the construction of a greenfield automated warehouse, featuring a 14-meter-high self-supporting structure with six aisles, each served by a dedicated stacker crane. The system handles:

- Metal bins up to 600 kg

- Europallets up to 1 ton

- Half-pallets

With nearly 14,400 storage locations, the warehouse uses double-deep storage for bins and half-pallets, and single-deep storage for full pallets. Inbound and outbound material flows are managed by five LGVs (Laser Guided Vehicles), ensuring continuous and automated handling.

The receiving area is equipped with advanced technology for dimensional and weight control, preventing handling issues. At the core of the system is LCS’s customized WMS, which manages all warehouse operations and integrates seamlessly with the company’s infrastructure, following Industry 4.0 principles.

In parallel, LCS implemented a Manufacturing Execution System (MES) that coordinates production across both the San Maurizio and Berzonno di Pogno plants. Connected directly to Cimberio’s ERP, the MES delivers real-time production recipes to manufacturing cells and provides detailed order tracking and performance monitoring. Data analysis enables fast, accurate evaluation of production metrics, supporting strategic decision-making based on reliable insights.

Thanks to this project, Cimberio has achieved key benefits:

- Space optimization, freeing up areas for new production cells and offices

- Digitalization and streamlining of internal logistics and production processes

- Error reduction through automation

- Improved ergonomics via “goods-to-man” systems and new picking stations

- Real-time monitoring of equipment status, order progress, and production times

In summary, Cimberio’s new Smart Factory 4.0 is a concrete example of how technological innovation can successfully enhance operational efficiency, workplace quality, and global competitiveness in the brass valve manufacturing industry.