Camar

The new Hi-Tech Automated Warehouse

Solutions

Automated Warehouse

Material Handling and Sorting

software

revamping

Sector

Manufacturer

Challenge

Camar, a global leader in the production of technical components for the furniture industry, needed to optimize intralogistics flow at its headquarters in Figino Serenza (CO). The storage area was divided into multiple zones, preventing a seamless connection between production and finished product shipping.

Solution

- Retrofit of the electromechanical components of the three existing stacker cranes

- Replacement of the head shuttle to connect with the new automated warehouse

- Upgrade of the automation PLC software, WCS for system supervision, and WMS for warehouse management

- Construction of a new self-supporting automated warehouse with four stacker cranes

- Building of an elevated bridge to connect the new warehouse to the existing one

- Expansion of the conveyor system serving the new production departments

- Implementation of the new automation, supervision, and warehouse management software

Key technical data

- Existing warehouse with 3,800 pallet locations on 15-meter-high racks

- New automated warehouse with four stacker cranes (H=17 m) for 6,200 load units

- Elevated bridge connecting the warehouses

- LCS proprietary software for automation, supervision, and warehouse management

Full description of the project

Camar, a global leader in the design and production of technical components for the furniture industry, has embarked on a significant logistics innovation journey, partnering with LCS to build a high-tech automated warehouse at its headquarters in Figino Serenza (CO).

Founded in 1960 in the heart of Italy’s renowned Brianza furniture district, Camar is known for its high-quality product range—including levelers, feet, wall cabinet supports, shelves, table bases, and legs—offering extensive customization options to meet global market demands.

To optimize intralogistics flows and enhance operational efficiency, Camar decided to overhaul its storage infrastructure, previously fragmented across multiple areas, which limited the fluidity of inbound and outbound operations.

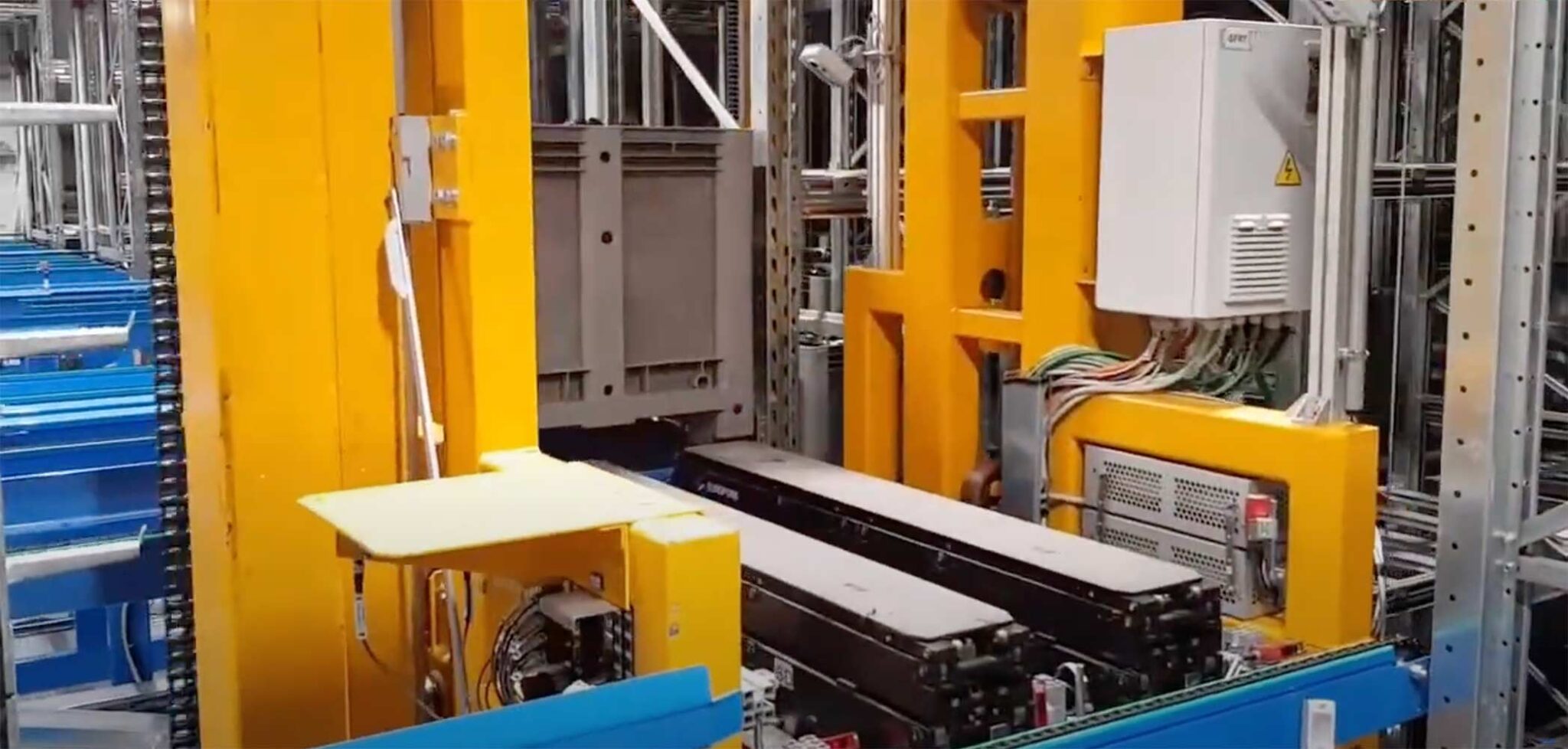

The project, entrusted to LCS, involved a complete revamping of the existing storage and handling system, originally installed in 1997. In just one month, LCS performed a retrofit of the electromechanical components of three existing stacker cranes, operating in single-depth racks 15 meters high, with a total capacity of 3,800 pallet positions.

To further boost performance, the head shuttle connecting to the new warehouse was replaced. Simultaneously, LCS engineered and built a 17-meter-high self-supporting automated warehouse, equipped with four stacker cranes and a capacity of 6,180 pallet positions.

A raised bridge was constructed to connect the new warehouse to the existing one, enabling seamless operation of the newly installed shuttle. The conveyor system was expanded to serve new production departments, and a new automation, supervision, and warehouse management software suite was implemented.

The system is managed by a customized LCS software package, which includes:

- A complete upgrade of PLC automation software

- A new WCS (Warehouse Control System) for equipment supervision

- A new WMS (Warehouse Management System) for inventory and logistics management

The solution was thoroughly tested prior to deployment to ensure compliance with the tight restart schedule. The warehouse operates across three levels:

- Ground floor: inbound goods, load unit (LU) identification and dimensional control, outbound LUs to production and shipping

- Second floor: inbound pallets from ground level via elevator

- Third floor: outbound LUs to production and return of finished goods to storage

Thanks to this intervention, Camar has centralized materials into a single warehouse, maximizing synergy between production departments and improving delivery speed. The new high-tech automated warehouse is a concrete example of how technological innovation can successfully optimize logistics processes and enhance customer satisfaction.