Cadel

The New Industry 4.0 Integrated Factory

Solutions

Automated Warehouse

Material Handling and Sorting

software

Sector

Manufacturer

Challenge

Cadel, an Italian company specializing in the design and manufacturing of high-quality stoves, required a new production facility to support its continuous growth. The new Integrated Factory needed to be highly technological, reliable, modular over time, and capable of meeting future demands.

Solution

- Self-supporting automated warehouse

- 10 production lines

- 8 finishing lines

- 9 AGVs (Automated Guided Vehicles) managing material flows

- Automated labeling system at each exit for labeling pallets before shipment

- Induction system embedded in the floor for AGV guidance and power supply

- Assembly and finishing line configuration managed by LCS software

- Advanced RFID reader system for pallet tracking throughout the facility

- LogiWare WMS software for automated warehouse management

- LogiCon/LogiDrive system for complete plant supervision and control

Key technical data

- Self-supporting structure: 21 meters high with 10 storage levels

- Three aisles served by stacker cranes, providing a total storage capacity of nearly 17,300 locations

- Double-deep storage for pallets and quadruple-deep storage for half-pallets

- Future expansion capability up to over 23,000 locations

- Fleet of 9 AGVs connecting different areas of the factory

- 10 assembly lines, 7 finishing lines, and 1 kitting line

- RFID system for real-time traceability of moved materials

Full description of the project

Cadel, a historic Italian company founded in 1949 and specialized in the production of pellet stoves, has taken a decisive strategic step toward innovation with the construction of a fully integrated smart factory, designed according to the most advanced Industry 4.0 principles.

Part of the MCZ Group since 2013, Cadel has successfully combined manufacturing tradition with technological innovation in a forward-looking project: the development of a new production site in Santa Lucia di Piave (Treviso). Covering approximately 18,000 square meters, the facility is a prime example of a smart manufacturing plant, where automation, digitalization, and sustainability coexist in perfect harmony.

The entire structure was designed with a modular logic, allowing for future expansions and ensuring adequate production capacity to meet growing market demand.

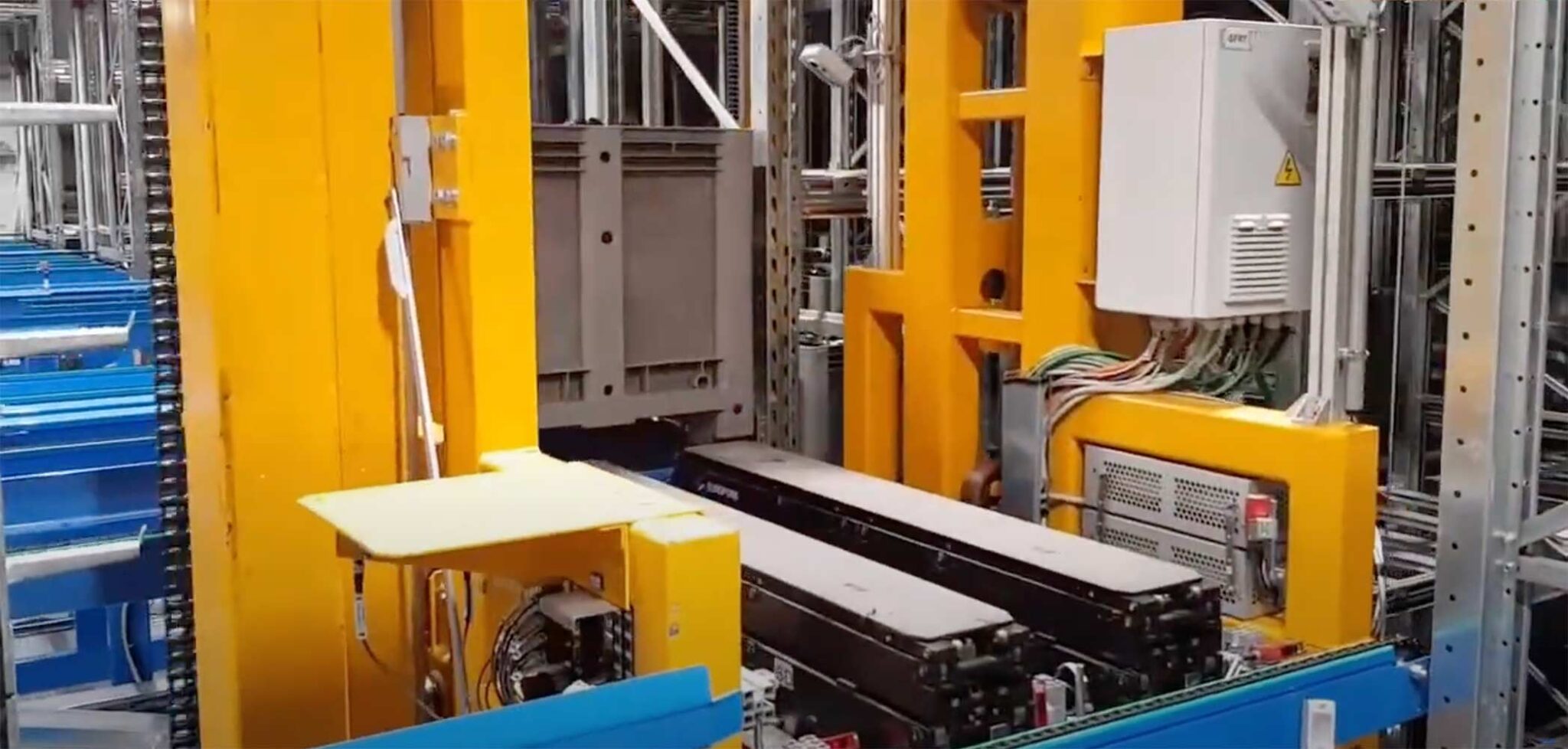

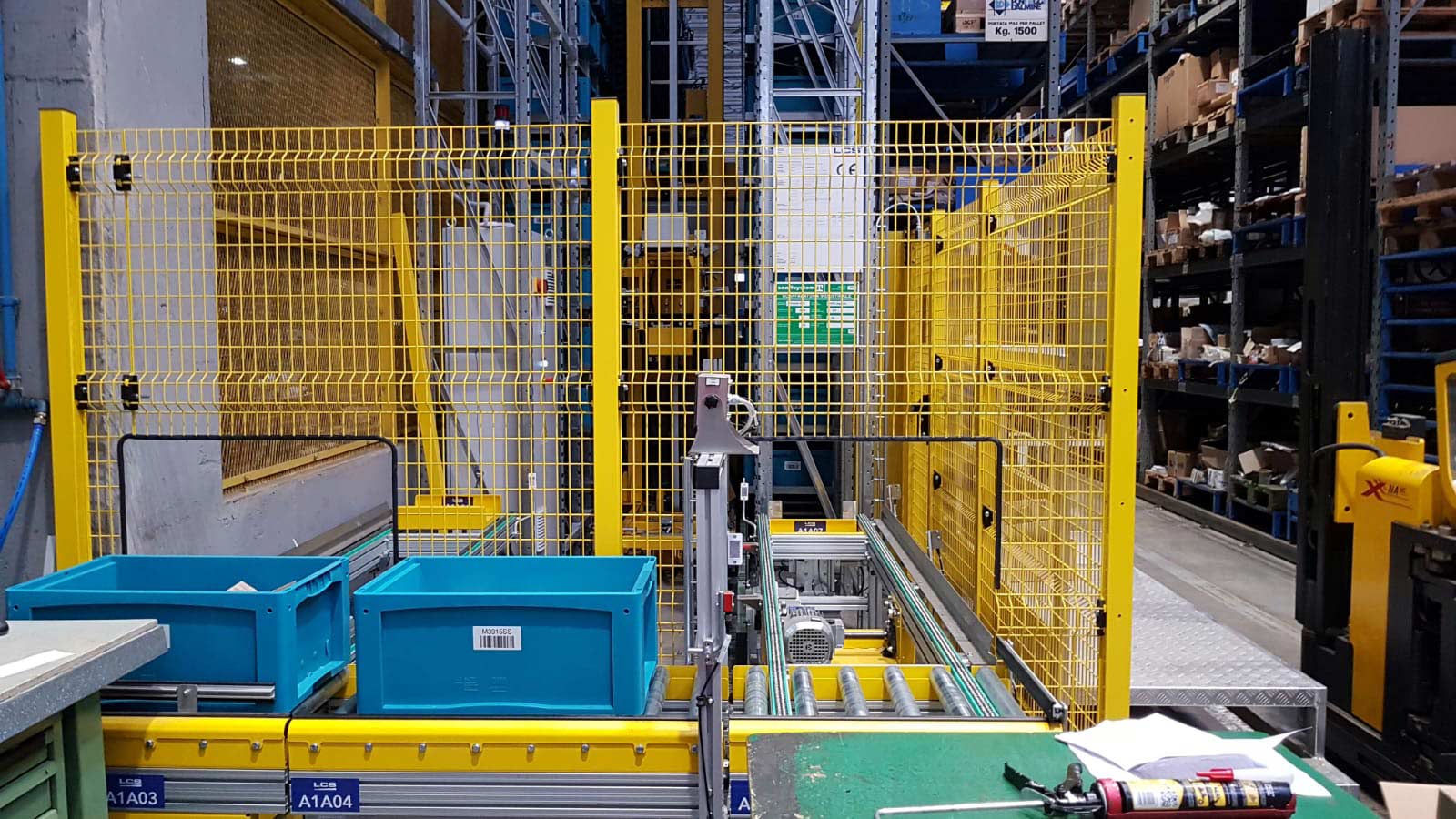

LCS played a central role in the development of this project, delivering a highly integrated and high-performance logistics solution. At the heart of the new factory is a 21-meter-high self-supporting automated warehouse, featuring ten vertical storage levels and three aisles, each served by next-generation stacker cranes.

Currently, the system accommodates nearly 17,300 pallet and half-pallet locations, with scalability up to 23,000 positions. Storage is optimized for maximum density: double-deep for pallets and quadruple-deep for half-pallets, ensuring high efficiency in both space utilization and handling speed.

The system includes shape control gates at inbound stations and automated labeling stations at outbound points, preparing pallets for shipment with maximum precision and traceability.

For internal material handling, Cadel adopted a sustainable and innovative solution: a fleet of nine AGVs (Automated Guided Vehicles) transports goods between production areas and the warehouse, following induction-guided paths embedded in the floor. This eliminates the need for lithium batteries, reducing environmental impact and simplifying charging operations. The AGVs operate autonomously and efficiently, ensuring a continuous and orderly material flow throughout the production line.

The entire production process has been redesigned to align with Industry 4.0 logic. The factory hosts:

- 10 assembly lines for semi-finished products

- 7 finishing lines

- 1 dedicated kitting line for final product customization based on customer specifications

This setup ensures maximum operational flexibility and minimal lead times, optimizing every phase of the production cycle. Workflows are perfectly synchronized: semi-finished products can be stored or sent directly to finishing lines, finished goods are routed to the automated warehouse or to the customization phase, and external kits are seamlessly integrated into the production chain.

Thanks to this fully integrated approach, Cadel has achieved significant results in terms of increased production capacity, waste reduction, and logistics efficiency. The new factory represents not only a technological evolution but also a paradigm shift in production management, based on real-time data, full traceability, and intelligent automation.

This project marks a turning point in the company’s history, reaffirming Cadel’s position as a European leader in pellet stove manufacturing, with a cutting-edge facility that combines product quality, fast delivery, and environmental responsibility—a true example of Italian excellence in smart manufacturing.