Galbusera

Revamping of stacker cranes and logistics optimization

Solutions

Automated Warehouse

software

revamping

Sector

Food & beverage

Challenge

In addition to significantly reducing floor storage space, the solution needed to efficiently and automatically feed production lines located on two floors while reducing crossing times.

Solution

- Revamping of stacker cranes.

- Implementation of LogiTRASLO software for stacker crane control.

- New pallet handling system.Introduction of conveyors with barcode reading, automatic labeling, and profile control.

- Automated sorting between warehouse and shipping.

- Elevator and shuttle for pallet transfer to the warehouse.

- LogiCON for system-wide supervision and control.

- LogiWare for automated warehouse management.

Key technical data

- Revamping of 4 stacker cranes with motor replacement, electrical panel upgrades, and software implementation.

- Automated pallet handling with conveyors, barcode readers, and elevators.

- Management software: LogiTRASLO (stacker cranes), LogiCON (supervision), LogiWare (WMS).

Full description of the project

Galbusera SpA, a historic Italian food company founded in 1938 in Morbegno, has long been a symbol of quality and tradition in the production of biscuits, crackers, and snacks. With a corporate philosophy rooted in customer care, transparency, and respect, Galbusera has earned a prominent position in both national and international markets, thanks to its commitment to premium raw materials and continuous pursuit of excellence.

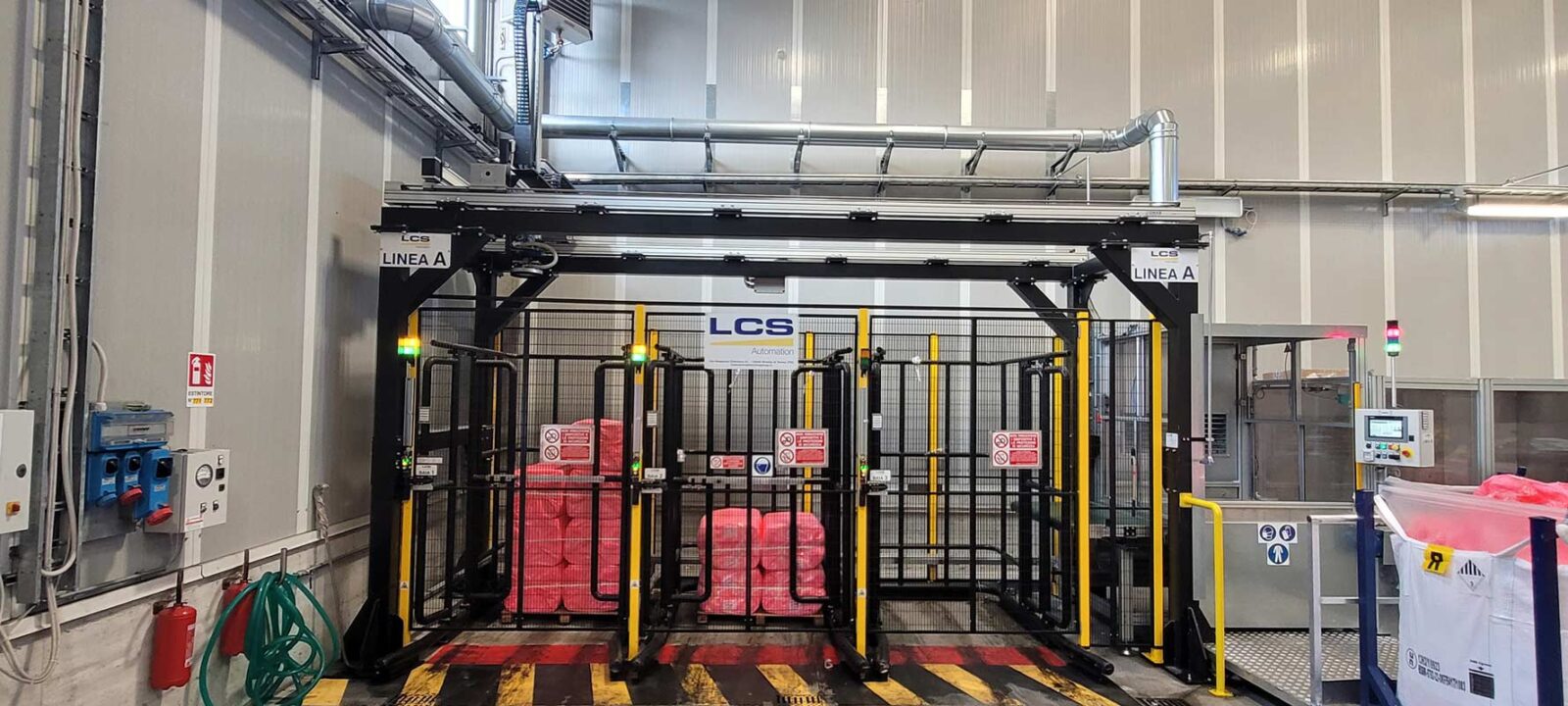

In line with this spirit of innovation, between late 2019 and early 2020, Galbusera launched a major revamping and automation project at its Cosio Valtellino facility, entrusting LCS with the modernization of its logistics and handling systems.

The intervention focused on streamlining logistics flows between production, warehouse, and shipping areas. The dual objective was to enhance existing infrastructure, particularly the automated warehouse, and decongest operational zones, while improving overall efficiency.

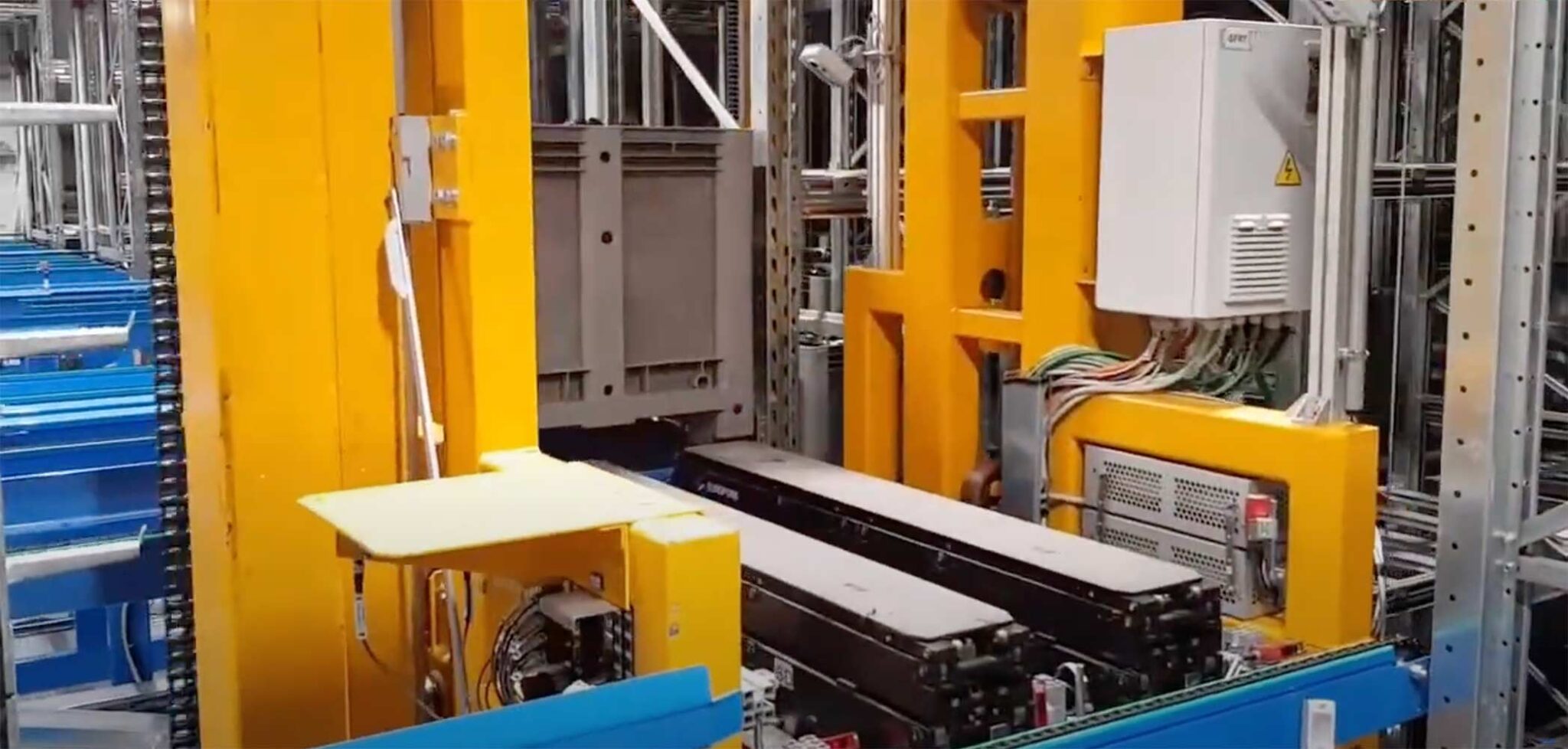

LCS carried out a complete retrofit of the four existing stacker cranes, including:

- Replacement of DC motors on two units

- Upgrade of onboard electrical panels

- Installation of new drives

- Integration of vision systems with cameras for ground-level fork group supervision

- Full update of the safety system in compliance with current regulations

New PLCs were installed for automation control, and a fully reengineered software suite based on LogiTRASLO was customized for Galbusera’s specific plant configuration. The system was completed with:

- LogiCON WCS for centralized supervision

- LogiWare WMS for automated warehouse management

In parallel, LCS designed and installed a new automated pallet handling system. Pallets from production are:

- Identified via barcode readers

- Automatically labeled

- Checked for dimensions using a shape control system

Based on collected data, pallets are routed either to the automated warehouse or to the shipping area. In case of anomalies, pallets are diverted to a dedicated station for manual inspection.

Pallets destined for shipping are automatically stacked by a shuttle with telescopic forks and lifting system, grouped by item type in six accumulation stations, ready for loading onto transport vehicles.

For storage, an elevator lifts pallets to 3.5 meters, allowing the shuttle to distribute them across four conveyor belts feeding the warehouse entrances. Stacker cranes then handle optimal placement within the warehouse. Outbound pallets are automatically routed to the shipping area, completing a fully integrated and automated handling cycle.

This strategic intervention enabled Galbusera to:

- Significantly boost operational efficiency

- Reduce handling times

- Improve logistics flow management

- Optimize use of existing infrastructure

The project is part of Galbusera’s broader modernization path, reinforcing its competitive edge and confirming its role as a benchmark in the food industry. It demonstrates how technological innovation can complement tradition to create lasting and tangible value.