Barilla

Revamping of stacker cranes and logistics optimization

Solutions

Automated Warehouse

software

revamping

Sector

Food & beverage

Challenge

The customer aimed to increase pallet storage capacity, improve storage and retrieval speed, and optimize logistics processes while maintaining existing metal structures and complying with building and performance constraints.

Solution

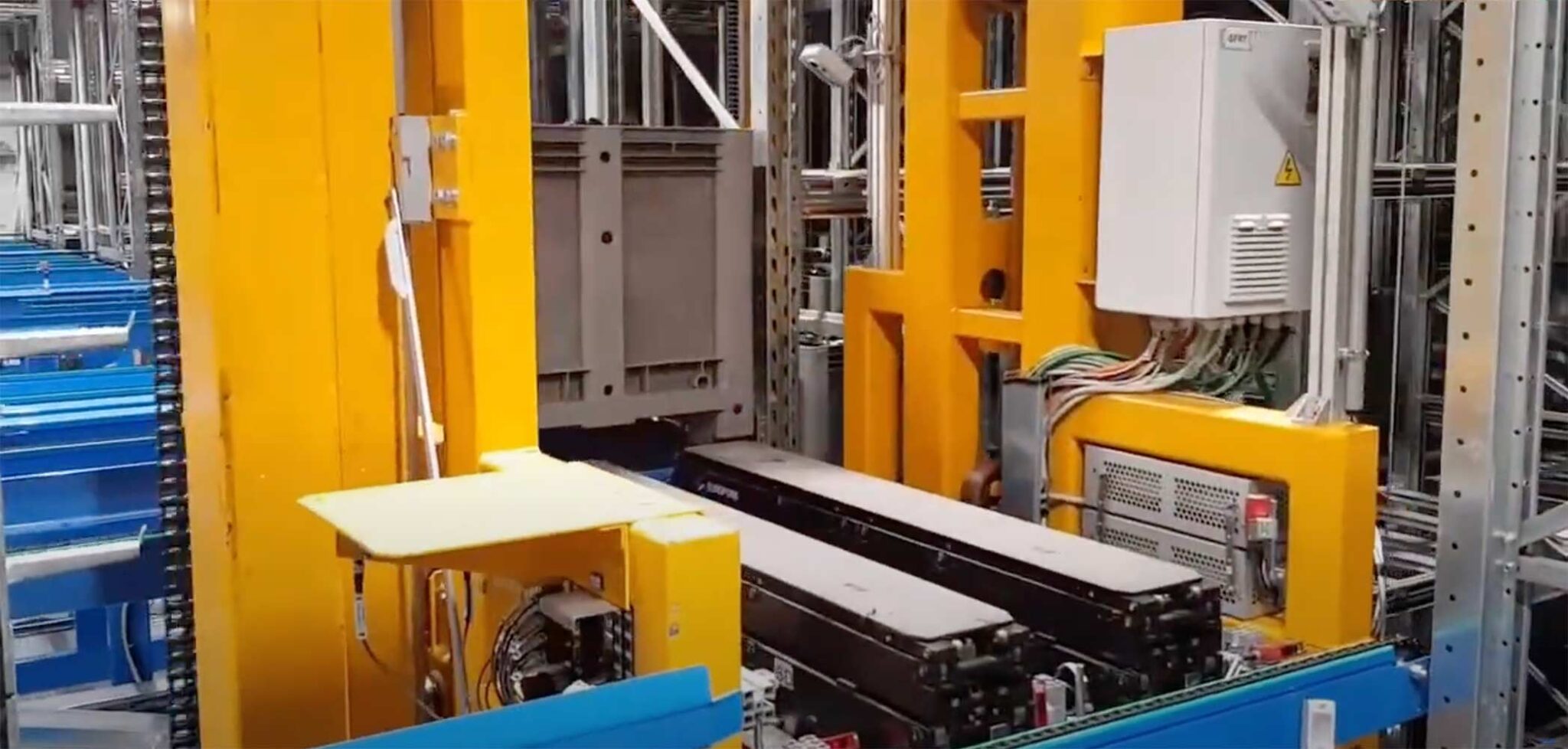

- Complete revamping of the existing warehouse, integrating pre-existing metal structures.

- Master shuttle technology with slave shuttles for efficient pallet management on five storage levels.

- Increased storage capacity by 6,500 pallet locations, optimizing available space.

- Handling speed of up to 60+60 cycles/hour (in and out), with high-efficiency devices operating at up to 240 meters per minute.

- Full supervision through LCS’s LogiWare software, managing both the automated and semi-automated warehouses.

- Implementation of advanced control systems, including 24/7 monitoring cameras and pallet tracking readers.

Key technical data

- +6,500 pallet locations added (from 12,000 to 18,500)

- 5 shuttles with onboard slave shuttles, one per rack level

- 2 elevators for pallet transport between levels

- 1 elevator for shuttle floor change in degraded mode

- LCS software for automation, supervision, and warehouse management

- 24/7 monitoring camera system and remote support maintenance contract

Full description of the project

Barilla, the historic Italian multinational founded in 1877 and a global leader in pasta, sauces, and bakery products, has launched an ambitious logistics modernization project at its Castiglione delle Stiviere facility in the province of Mantua.

With an annual production exceeding 1.9 million tons and a network of 28 manufacturing sites, Barilla chose to upgrade an existing, outdated structure by transforming it into a state-of-the-art automated warehouse, aligned with the company’s long-standing commitment to innovation and sustainability.

The project had two main objectives:

- Increase storage capacity to meet rising product demand

- Optimize storage and retrieval operations while maintaining a “goods-to-person” approach and improving ergonomic conditions for warehouse staff

Entrusted to LCS, a specialist in intralogistics solutions, the project involved a complete revamp of the existing automated system, preserving the original steel structures and adhering to the building’s dimensional constraints.

In collaboration with Dalmine Marcegaglia for structural and civil works, LCS engineered a solution based on master shuttle technology with slave shuttles, enabling fast and precise pallet handling.

The new automated warehouse spans 40 meters in width, featuring a central aisle surrounded by five storage levels, totaling 400 deep storage channels (14 meters each). Pallets pass through weight and shape verification stations before being transported across the levels by master shuttles (traveling up to 240 m/min) and slave shuttles, which automatically deposit or retrieve pallets based on current orders, expiration dates, and inbound/outbound protocols.

The system handles 60 inbound and 60 outbound cycles per hour, ensuring a continuous and optimized goods flow.

Operations are managed by LogiWare, LCS’s proprietary software, which also controls the semi-automated warehouse on-site, providing full integration across operational areas and real-time supervision of all storage and handling activities.

Thanks to this upgrade, Barilla has increased its storage capacity by approximately 6,500 pallet positions, significantly reducing costs associated with shuttling and external storage, and transforming a previously underutilized area into a strategic asset.

This project exemplifies how the synergy between engineering expertise, advanced technology, and strategic vision can deliver tangible and lasting results, reinforcing Barilla’s position as a market leader and a pioneer in sustainable and innovative logistics solutions.