Aerial Vision

Sorter solution for automatic sorting of glasses

Solutions

Material Handling and Sorting

Sector

Distribution & e-commerce

Challenge

Aerial Vision required an automated sorting system to improve inbound goods management, optimise shipments, and simplify inventory. The existing manual process slowed down operations and could lead to errors, making a more efficient and traceable system essential.

Solution

- Automate the sorting of packaged glasses, reducing the risk of manual errors.

- Integrate a 1D/2D barcode reading portal to identify each item and assign it to the correct destination.

- Manage up to 51 sorting outputs via gravity chutes with pneumatic pushers.

- Connect the sorter to the ERP system to ensure traceability and real-time updates.

- Increase operational efficiency with a productivity of 3,600 items/hour.

Key technical data

- Sorter with 51 sorting chutes

- Portal with 1D/2D barcode readers for automatic identification

- Sorting at a speed of 3,600 items/hour

- Management of different types of packaging (bags, boxes, envelopes)

- Integration with the ERP system for real-time updates

Full description of the project

LCS has developed a high-efficiency automated logistics solution for Aerial Vision International, tailored to meet the complex and specific needs of the optical sector, particularly in the handling and sorting of items such as eyeglasses and related accessories.

Aerial Vision is an Italian company operating in wholesale trade and import-export of optical products, with a growing focus on the e-commerce channel, which demands speed, accuracy, and the ability to manage high order volumes within tight timeframes.

The project aimed to optimize logistics operations including goods reception, cataloging, and shipment of items packed in various types of packaging. The goals were to improve warehouse management, order fulfillment, and inventory accuracy, while reducing human error and operational time.

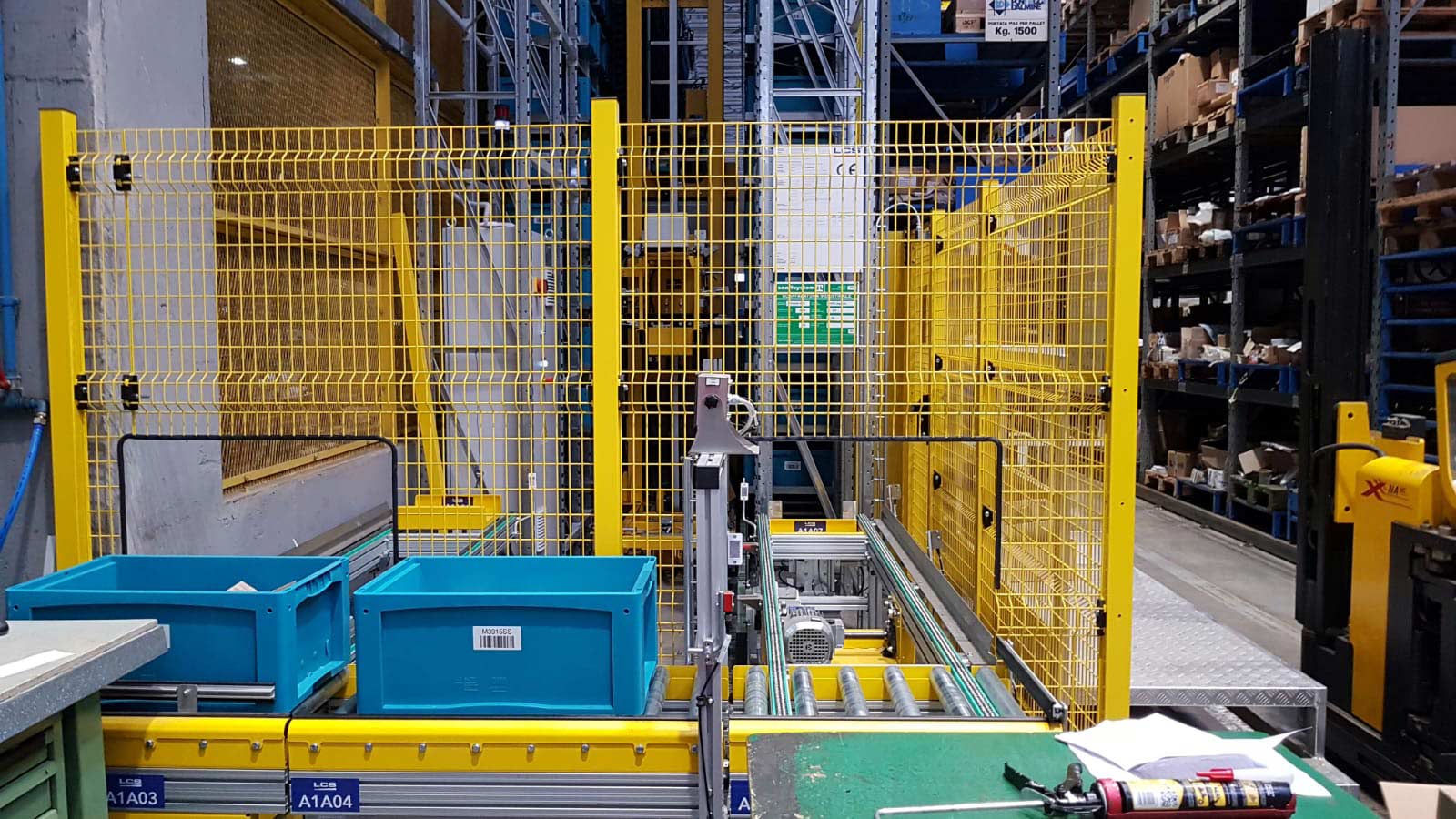

At the core of the solution is a high-performance automated sorting system, featuring a sorter configured to identify and route incoming products. Each item is labeled with a unique barcode, allowing the system to recognize and sort them across 51 dedicated chutes, each linked to a specific logistics destination—from warehouse storage to online order preparation, and direct customer shipping.

The system employs fast and precise pneumatic pushers, ensuring safe handling of items without damaging their contents, even when dealing with fragile packaging such as eyeglass cases.

The entire process is managed by LogiCon, LCS’s proprietary software platform, which provides fully integrated operational control. LogiCon interfaces directly with Aerial Vision’s ERP system, enabling real-time data exchange that keeps physical and informational flows aligned. This allows the company to continuously monitor product status, location within the logistics cycle, movement history, and inventory levels.

Additionally, the system offers advanced traceability and tracking features, essential for ensuring quality, reliability, and transparency throughout the supply chain.

Thanks to process automation and software integration, Aerial Vision has significantly reduced errors from manual handling, improved order response times, increased daily fulfillment capacity, and enhanced service speed and accuracy for its customers.

This project showcases how the synergy between engineering expertise, technology, and strategic vision can deliver tangible benefits to dynamic commercial enterprises, especially those operating in e-commerce and international distribution.

LCS’s intervention marks a key milestone in Aerial Vision’s journey toward modern, automated, and future-ready logistics.