Service

Flexible Maintenance and Rapid Support for Efficiency and Business Continuity

With a customer-oriented approach, LCS Group offers flexible maintenance contracts, adaptable to specific operational needs, ensuring rapid response times and always-available technical support.

The combination of advanced technical expertise and cutting-edge technological solutions makes our Service Division a reference partner for companies aiming to maximize efficiency and production continuity.

Plant management with resident technicians

Training and education

24/7 technical support

Routine and non-routine maintenance

Spare parts management

Plant management

with resident

technicians

Training and

education

Technical

support 24/7

Routine and

non-routine

maintenance

Spare parts

management

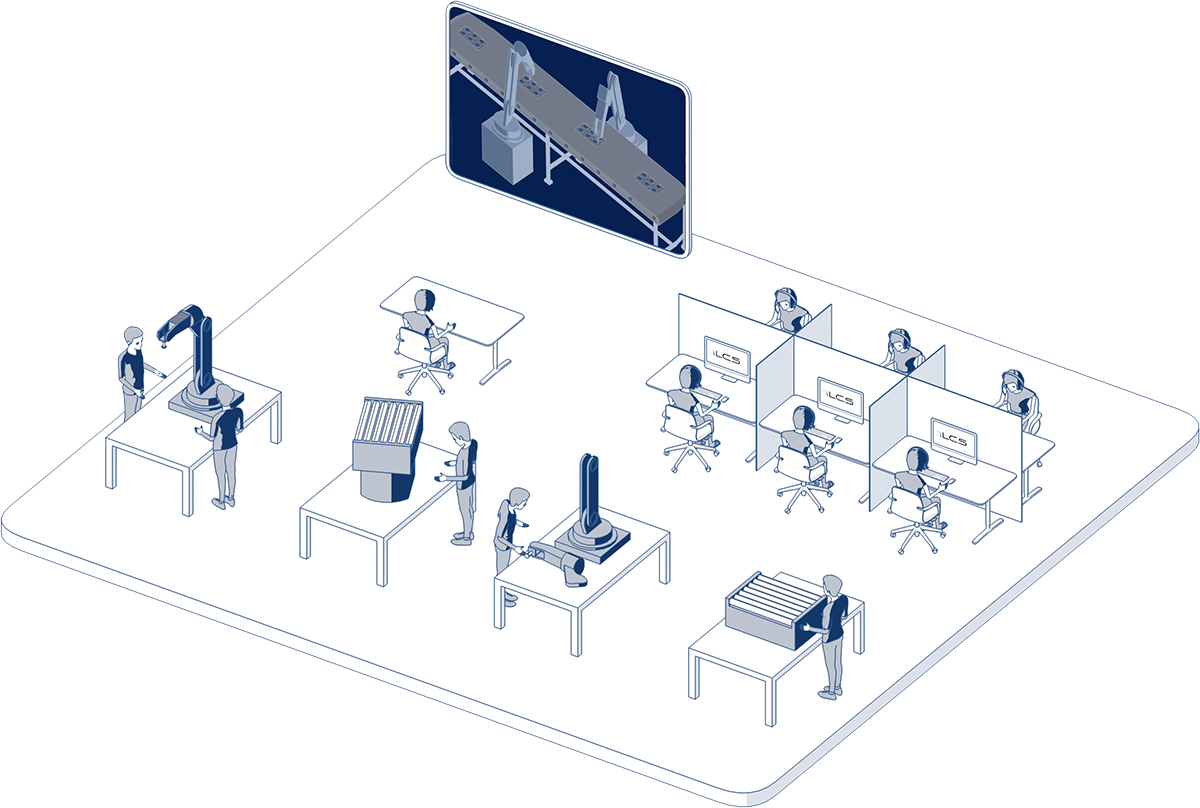

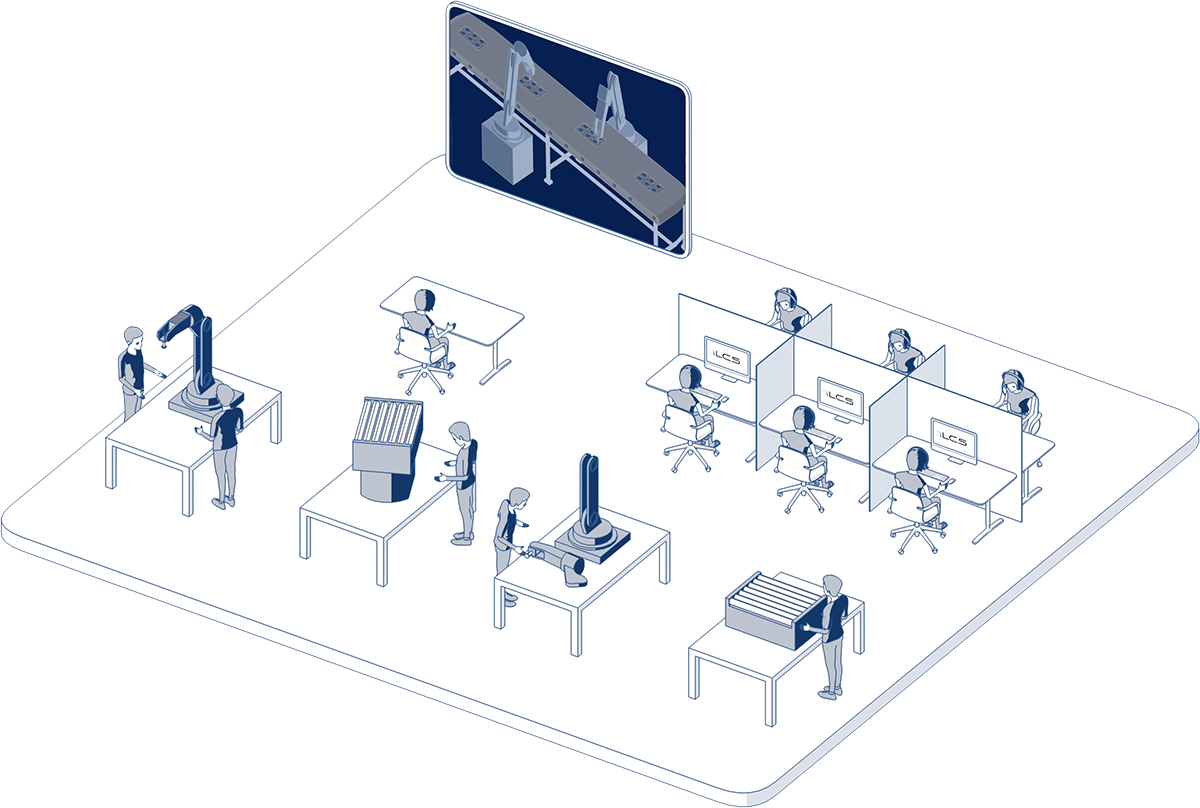

3D demo of back-office, service, and electromechanical support department operations

Preventive Maintenance

Preventive maintenance is carried out by a specialized team, supported by a well-structured organization with dedicated departments to ensure full coverage:

Electromechanical Department

Handles monitoring, wear control, maintenance, and replacement of hardware components.

PLC Department

Manages maintenance and updates of industrial control systems.

PC Department

Provides support and updates for software and user interfaces.

Back Office

Coordinates requests, schedules interventions, and monitors results.

Corrective and Extraordinary Maintenance

LCS provides extraordinary maintenance services beyond standard system management.

These interventions are performed whenever urgent action is required to restore operations.

LCS supports its customers in all emergency situations, ensuring uninterrupted operations.

24/7 Assistance

We provide round-the-clock support, available 24 hours a day, 7 days a week, with flexible coverage options (from 5×8 to 7×24) and rapid response times:

• Remote support within 2 hours

• On-site support within the next working day

Plant Co-Management

LCS offers plant co-management services, supporting customers in the day-to-day operation of their infrastructures.

Thanks to the expertise of our specialists, we ensure an effective transfer of know-how, gradually guiding customer teams to optimize operations.

Spare Parts Management

We help customers minimize downtime and extend the lifecycle of their systems by monitoring and replacing spare parts according to their obsolescence status.

Through a well-planned inventory system and collaboration with qualified suppliers, we provide timely replacement and installation of obsolete components.

Upgrades and Modifications

We deliver hardware and software upgrades to adapt systems to evolving operational requirements.

Thanks to direct contact with our back office, customers can submit new requests at any time, which are promptly evaluated by our technical team.

Training Programs

LCS provides customized training programs for customer personnel, aimed at optimizing system usage and maintaining up-to-date technical skills.

Our courses, led by certified experts, cover correct use of technologies, operational best practices, and safety standards, ensuring maximum productivity and compliance.

Performance Monitoring

With our advanced monitoring tools, LCS tracks plant performance in real time, providing detailed analyses to identify improvement opportunities.

This proactive approach enables our customers to maximize efficiency, reduce operating costs, and maintain the highest quality standards.